Inclusion Detection in prepreg layup based fabrication process

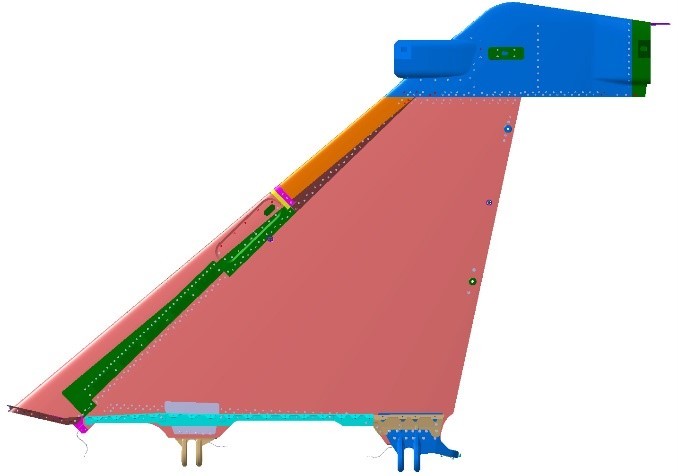

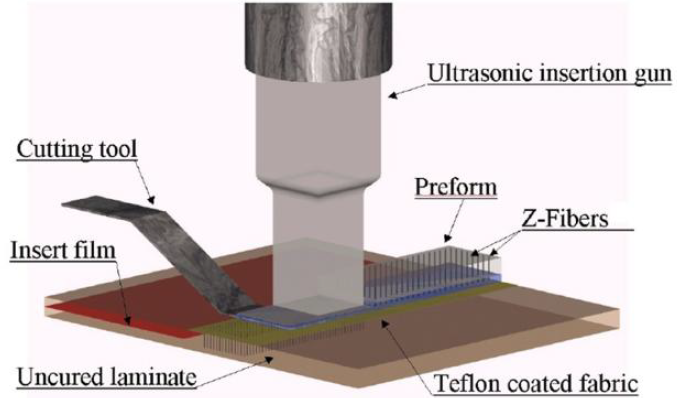

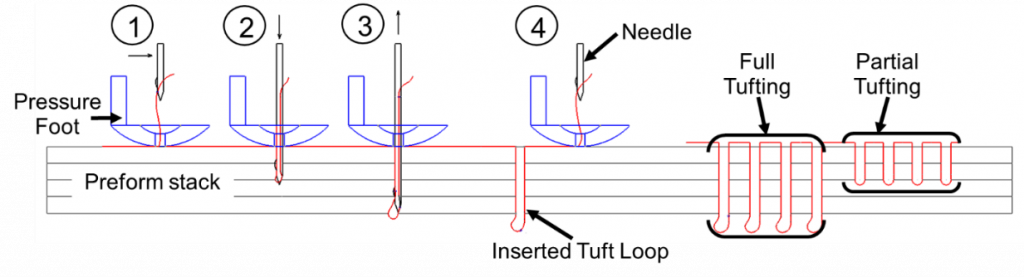

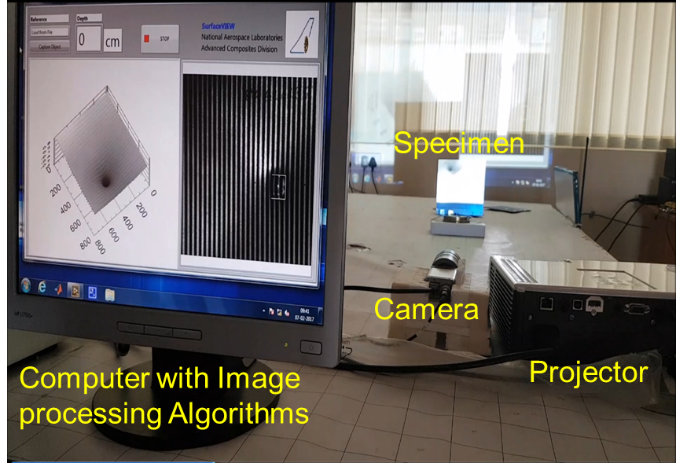

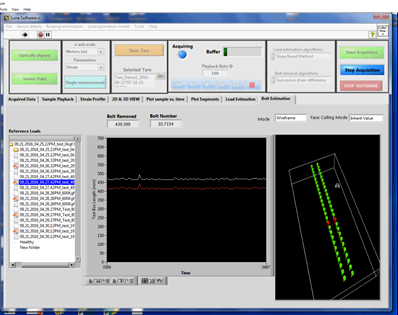

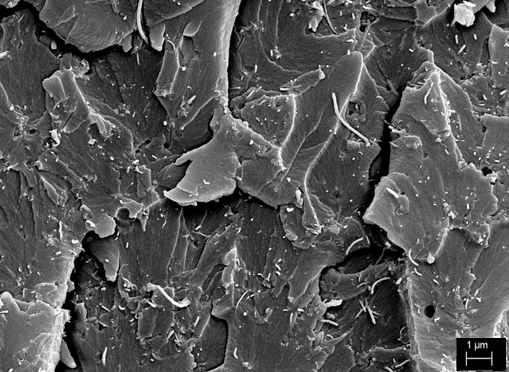

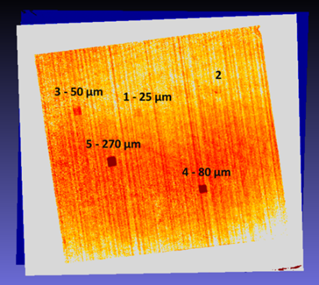

One of the major concerns during manufacturing process of composite parts using prepregs is the occurrence of accidental inclusions like release film, prepreg back up film and the like in composite layup. Inclusions cause delaminations or disbonds in the parts manufactured if they not detected and removed from the layup at layup stage itself. More often than not, a part with embedded inclusions is rejected which has cost and time implications for the program. Generally, the prepreg layup is checked by a clean room inspector ply-by-ply by manual visual inspection for inclusions. Such an inspection depends on the skill and alertness of the inspector and occasionally, the inclusions might go unnoticed by the inspector. As inclusions manifest as surface thickness variations, a methodology using 3D laser scanning technology is under development. These inclusions are very thin and in the range of 30 microns to 180 microns. After placing each layer and debulking, the surface profile of layer will be scanned using a laser scanner to get a point cloud data. In-house developed algorithms will be used to analyse the point cloud data which will identify the location of inclusions (if present). This technique will be a great tool to the inspector for detecting the accidental inclusions more efficiently, thereby reducing the chances of the part getting rejected.

|

|

|

|

|

Layup with Inclusions |

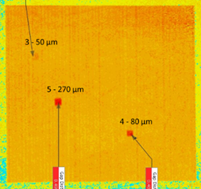

Laser Scanner data (OEM) |

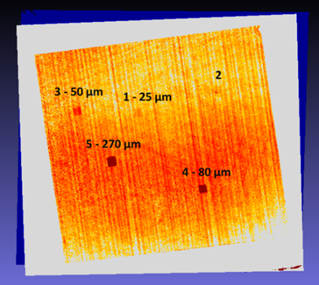

Data after Analysis |

English

English हिन्दी

हिन्दी