Z pinning

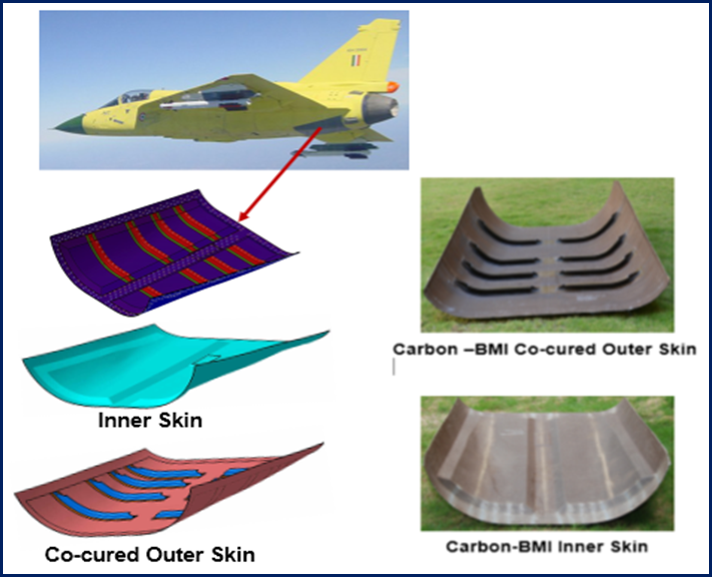

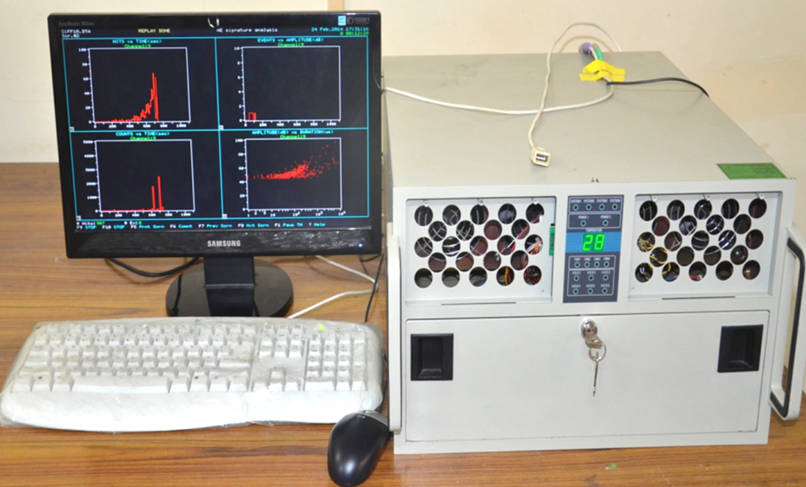

Cocured composite structures are being employed in order to reduce part count, assembly time and associated costs. Carbon fiber reinforced polymer laminates are prone to delamination because of low velocity impacts. These impact damages reduce the load carrying capacity of the structure. The delamination between skin and stiffener is a matter of concern to designers under fatigue loading. Researchers around the world are looking at techniques to improve the through the thickness properties to mitigate the delamination growth.

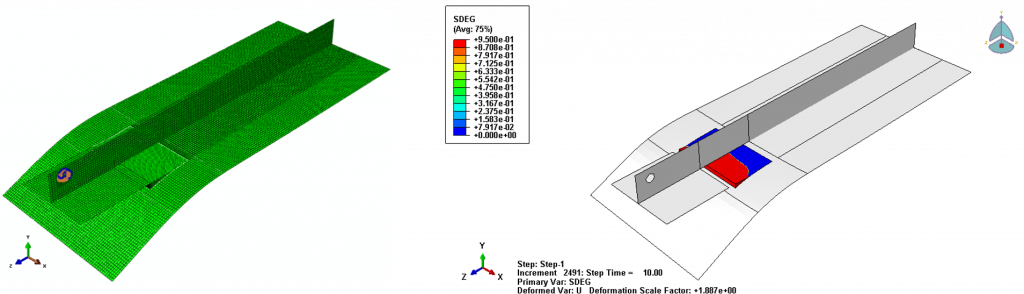

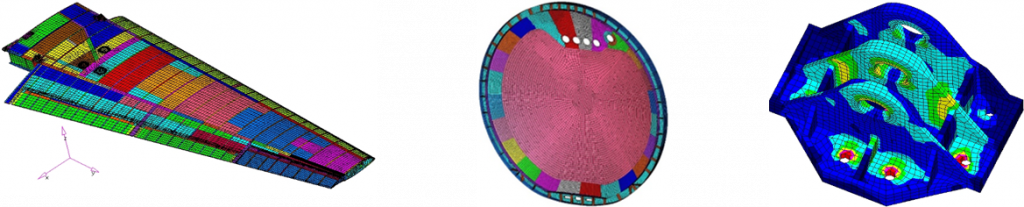

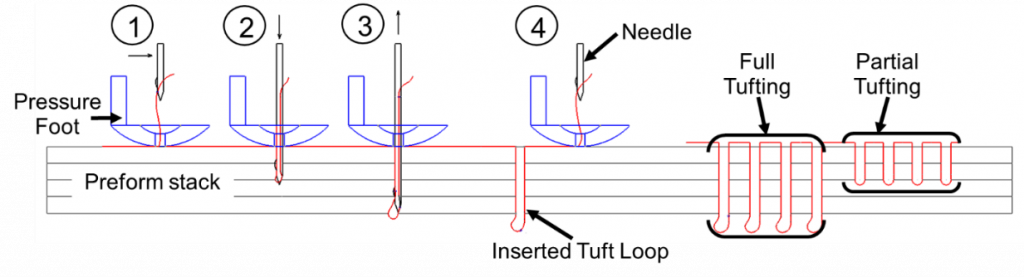

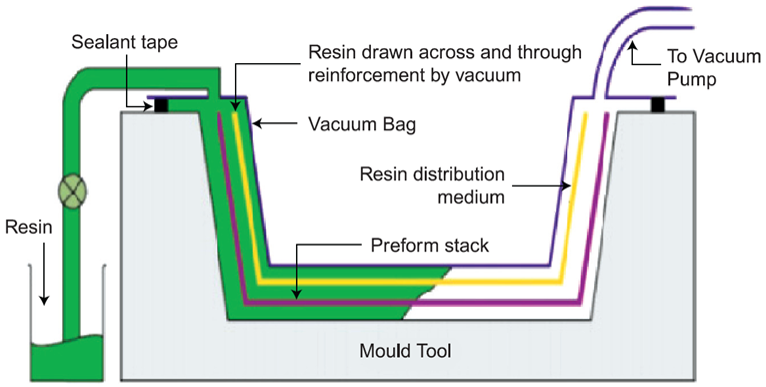

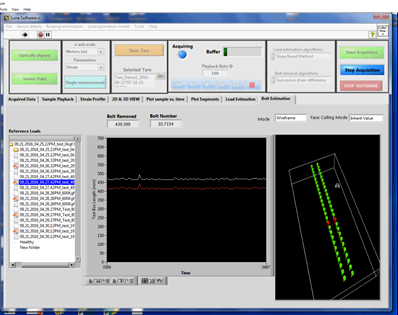

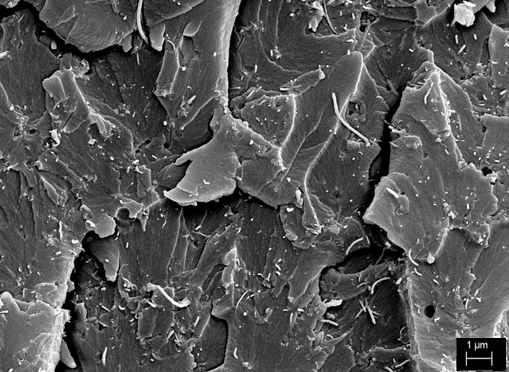

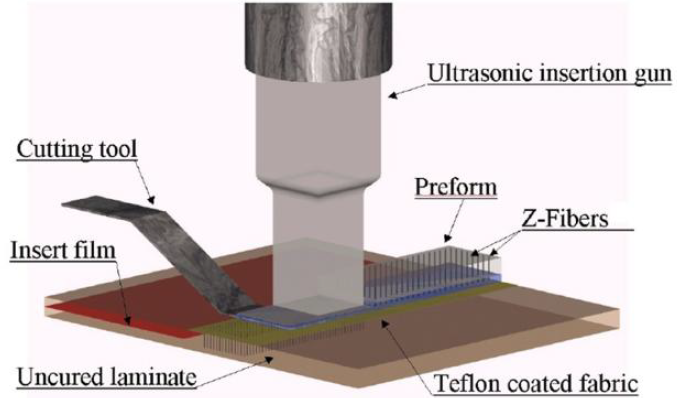

Z-pinning is a through-thickness reinforcement technology, which increases delamination resistance, post impact toughness and joint strength of composites. Z-Pinning works on Ultrasonically Assisted Z-Fiber® process developed by Aztex Inc and is currently the most widely used method of pinning composites. An ultrasonically actuated gun operating at a frequency of 20 kHz with a solid metal contact surface is used to drive Z-pins from the foam preform into the green stage composite. The high frequency ultrasonic vibrations reduce the force required to insert the pins. Heat generated by this vibrations assist the insertion of pins by softening the matrix resin in the prepreg. Z-pins are made of Carbon/BMI material having 0.28 mm pin diameter, 15 mm length and areal densities of 2% and 4%. Pins are embedded in a foam block with varying density to facilitate insertion.

Specifications:

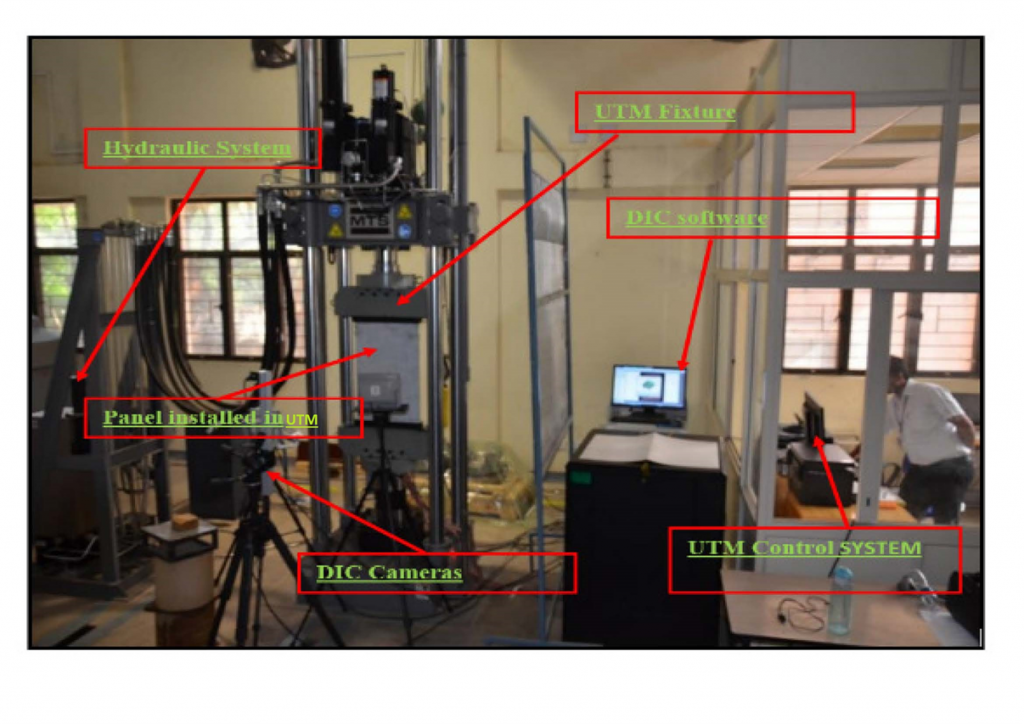

ACD has facilities for Z-pinning either by manually or by automated robotic facility.

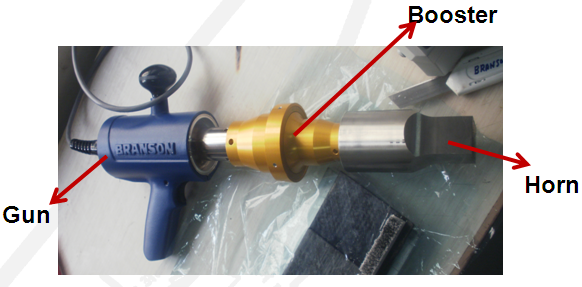

Hand Held Ultrasonic Gun (Manual Method):

Frequency: 20 kHz, Output power: 500 Watts, Supplier: Branson Ultrasonics.

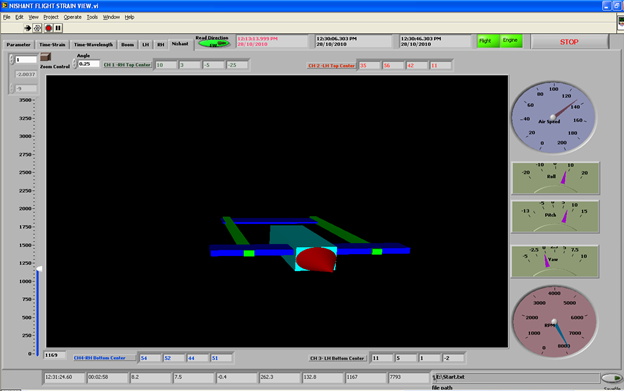

Robotic Tufting Facility (Automated method):

Robot controlled automated Z-pinning head aids in orthogonal insertion of Z-pins in the composite prepreg material. Robot controls helps in driving Z-pins at specified angle and to required depth precisely. Automation eliminates the human errors that is caused in manual pinning method, which has adverse effects on the properties of pinned laminates.

Z-pinning Head Specs

Frequency: 20 kHz

Power rating: 2500 Watts.

Z-Pin Specs:

Material: BMI/Carbon, Pin diameter: 0.28 mm, Density: 2% & 4%, Pin Length: 15 mm

Size: ½” X 12” strip, Supplier: Albany Engineered Composites

Major mile stones / results of this technique:

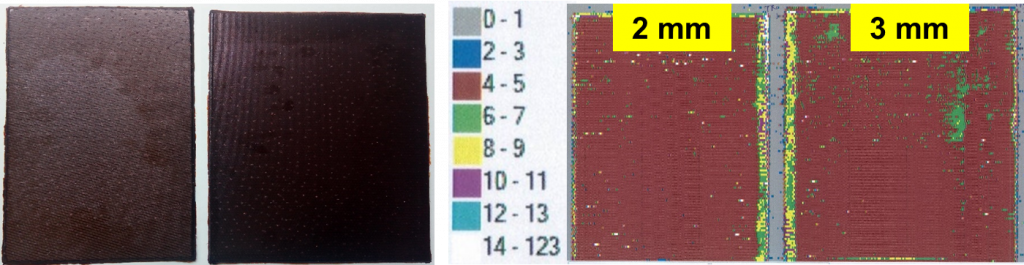

- Various process parameters like Z-pin insertion angle, column effect and removal of foam and debris are studied.

- Based on the Ultrasonic C-scan on z-pinned laminates, process parameters are fine-tuned and the proper caul plate design is arrived at to minimize the column effect.

- Preliminary testing is done to evaluate the effect of Z-pins on the in-plane properties like tension, and compression strengths of un-notched and notched laminates at ambient conditions. A general trend of reduction in strength for in-plane properties is noticed due to Z-pinning which was attributed to fiber kink, local damage to fibers at Z-pin area and resin rich areas. Even though strength reductions are higher in un-notched strength of UD and quasi-isotropic (QI) specimens, the reduction in strength of notched specimens is meagre.

English

English हिन्दी

हिन्दी