Autoclave molding

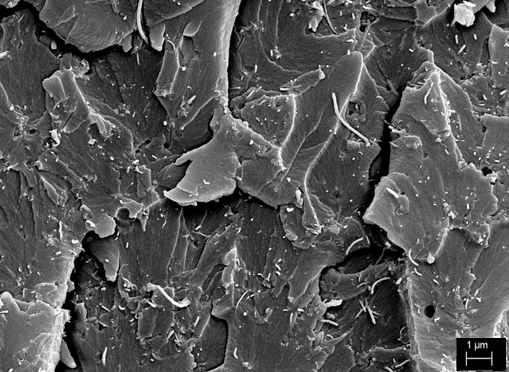

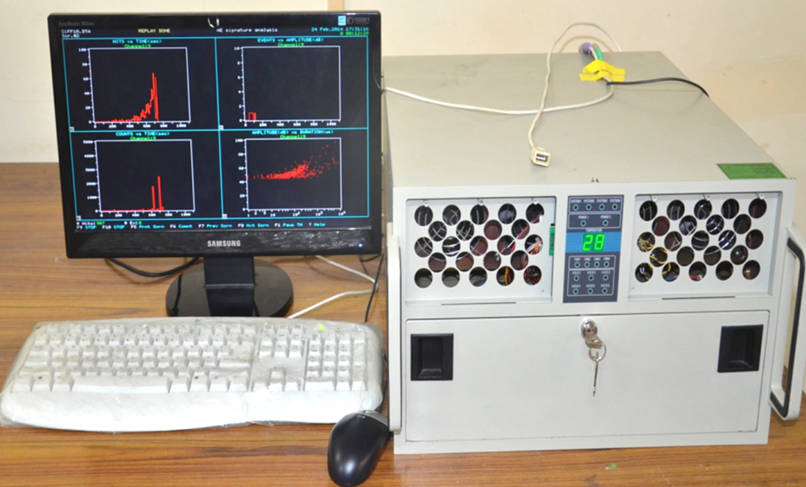

Autoclave molding technique is an advanced composite manufacturing process. It is widely used in the aerospace industry to fabricate high strength / weight ratio parts from pre impregnated high strength fibers. This method employs an autoclave to provide heat and pressure to the composite material (prepregs) during curing. In this method, prepregs are stacked in a mold in a definite sequence and the whole assembly is vacuum bagged to remove any air entrapped in between the layers. Rated heat and pressure is applied for a definite interval of time based on the material specifications. During the process, matrix is uniformly distributed and makes intimate contact and proper bonding with fibers. After processing, the assembly is cooled to a definite rate and then vacuum bag is removed. Autoclave moulding technique produces composite parts with fiber volume fractions as high as 60% and void content less than 1% and considered as a benchmarking process for comparison.

Specifications: ACD has four autoclaves of different sizes and ratings for processing resins like Epoxies, Bismaleimide, Polyphenylene Sulphide (PPS) and Polyimides.

Major mile stones / results of this technique:

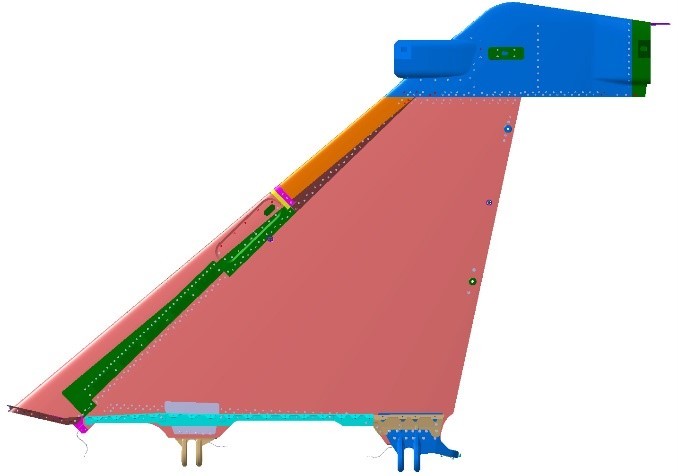

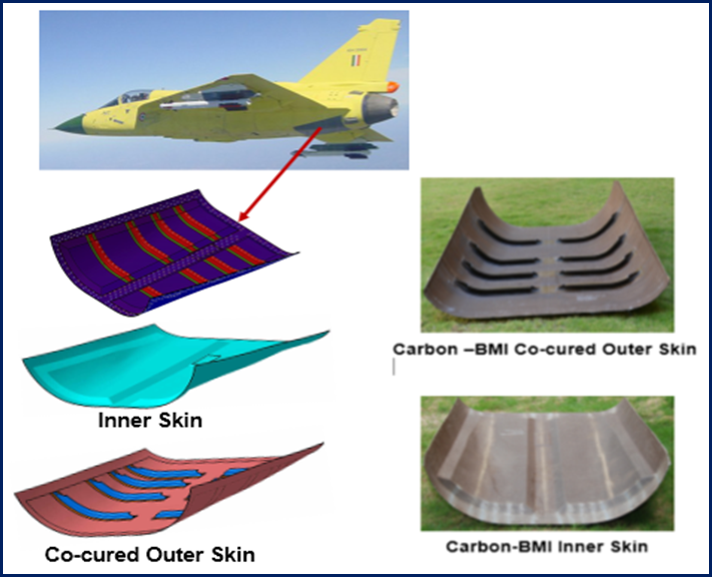

- Autoclave moulding technique is successfully utilised to realise cocured composite structures for national programs like LCA-Tejas and SARAS airframes. The parts produced have met airworthiness standards as specified by regulatory bodies.

English

English हिन्दी

हिन्दी