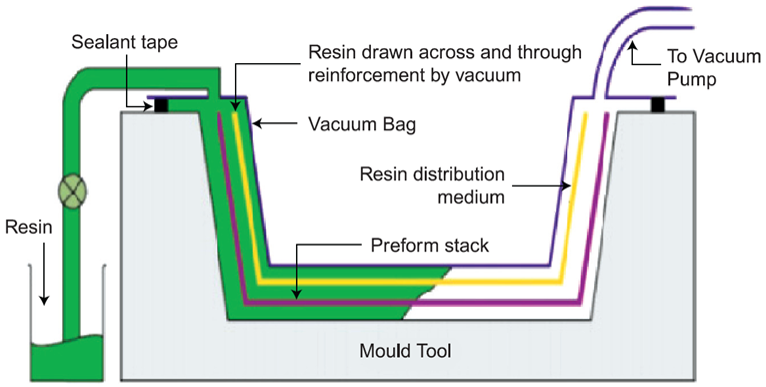

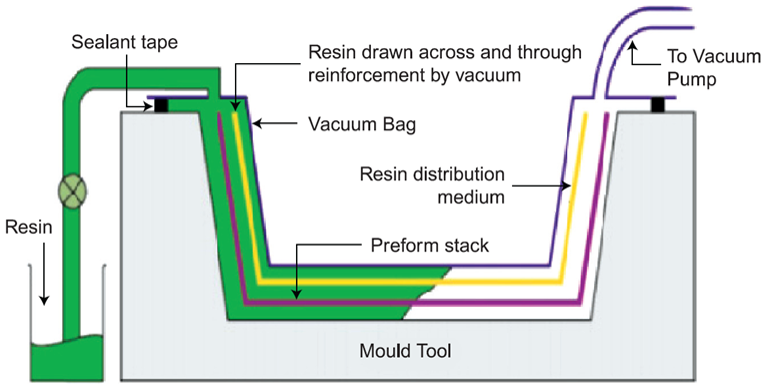

Vacuum Enhanced Resin Infusion Technology

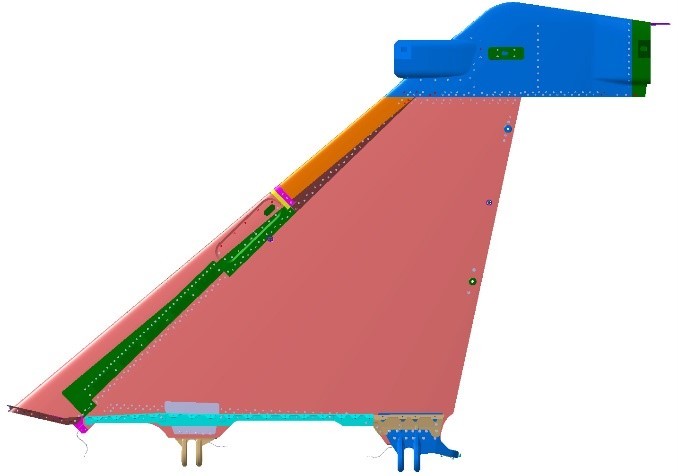

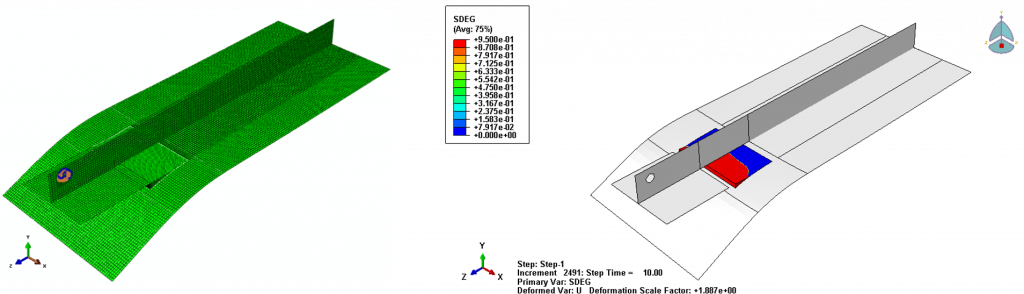

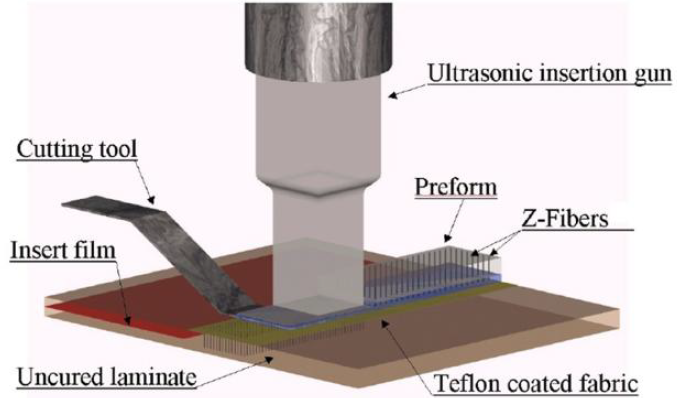

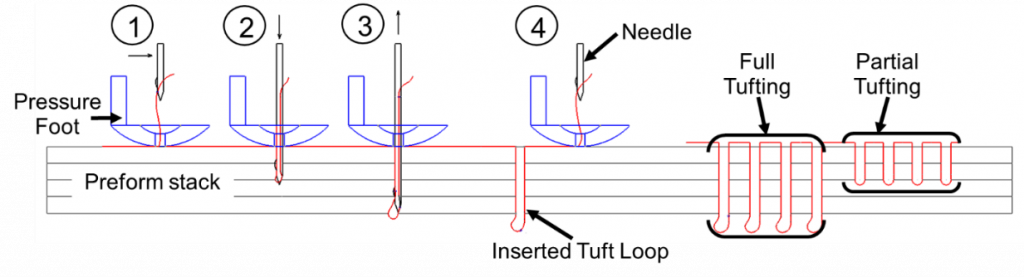

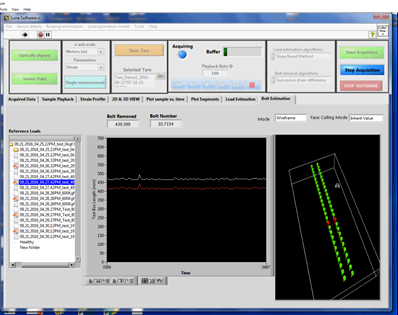

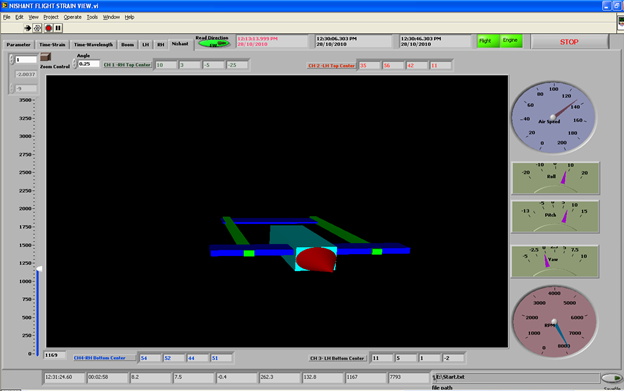

Majority of aerospace composite components are manufactured using prepreg / autoclave moulding process. Prepregs are perishable materials and have limited life. Prepregs have to be stored at -18°C which adds cost to the final product. In order to have a cost effective manufacturing process for a primary structure, the team at ACD developed a proprietary process called VERITy. The principle of VERITy is that the reinforcement is held in a tool cavity and infused with resin and a differential pressure is maintained using vacuum to impregnate fibers as depicted in the schematic. The impregnated preform is then cured in an autoclave. During cure, prior to gelation, an external pressure is applied in order to achieve required fibre volume fraction and better compaction and to ensure proper consolidation especially at cocured joints and thicker regions.

Schematic of VERITy Process

Salient features

- Relatively low cost for low volume production

- Low cost of tooling

- Possibility of manufacturing of very large and complex parts

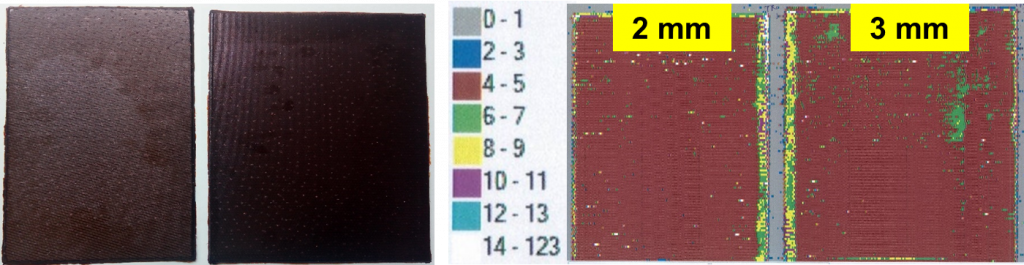

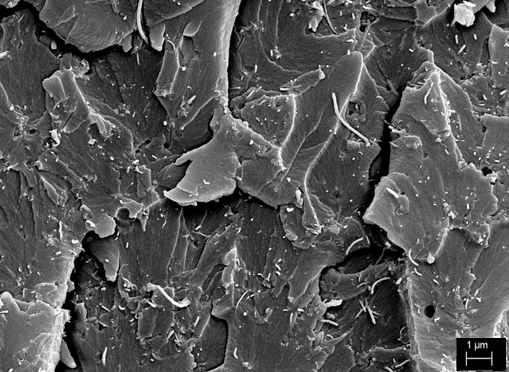

- High fiber volume fraction (58-60%) with low void content (less than 1%)

Major mile stones / results of this technique

- Properties nearly equivalent to autoclave moulding are achieved

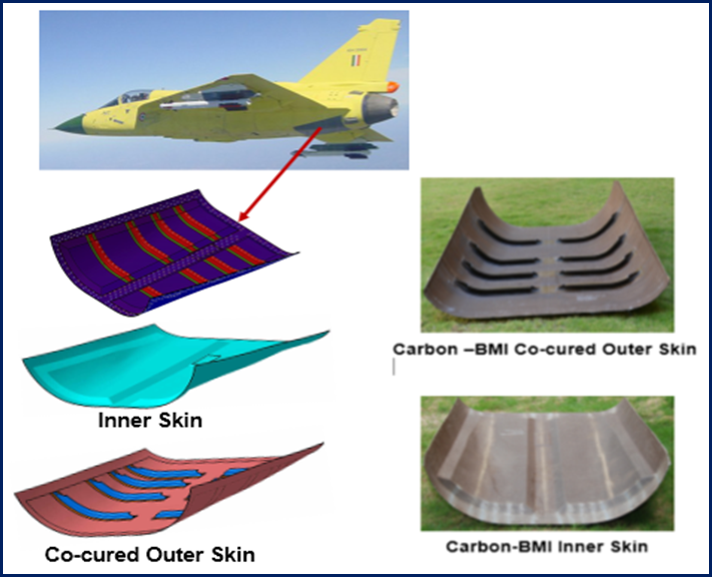

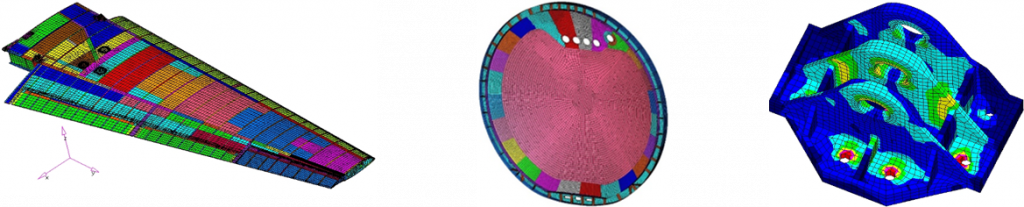

- Cocured outboard and inboard complex SARAS wing components are successfully manufactured using VERITy process

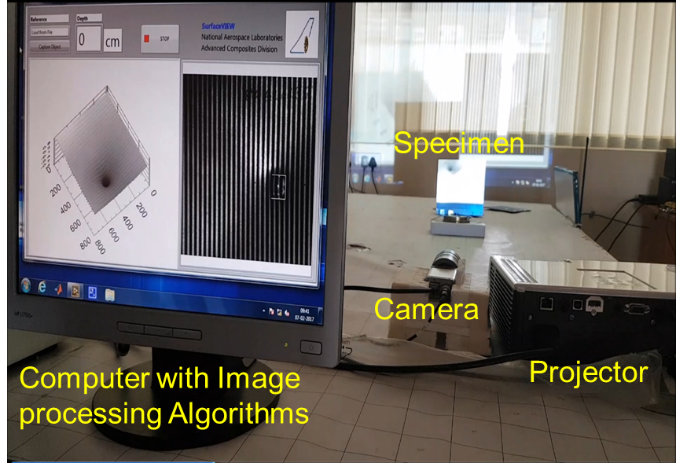

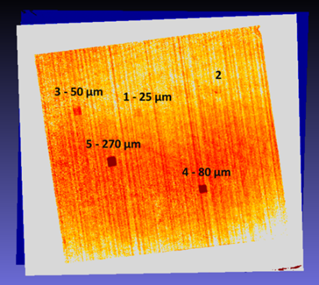

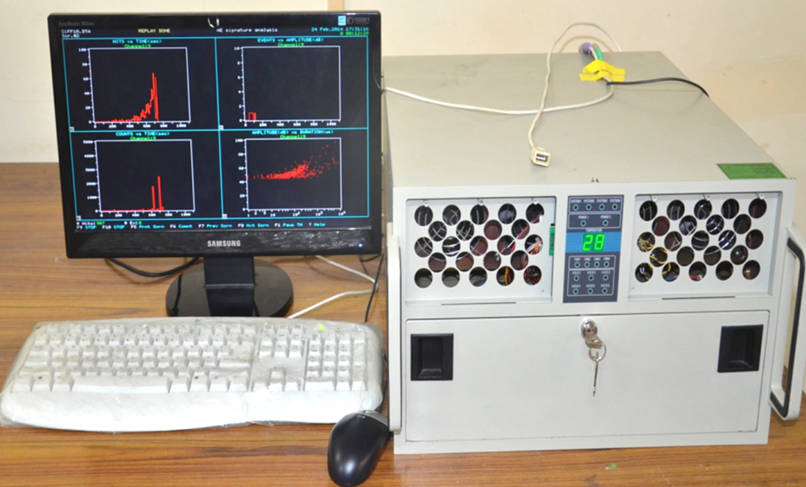

- Components are successfully qualified using ultrasonic C-scan

- The development of infusion technology for SARAS Wing received JEC Asia innovation award in thermoset category in 2015 and 7th National award for technology innovation in petrochemicals and downstream plastic processing industry’, 2016-17 for Research in the field of Polymer Science and Technology by the ministry of chemicals and fertilizers, Govt of India

English

English हिन्दी

हिन्दी