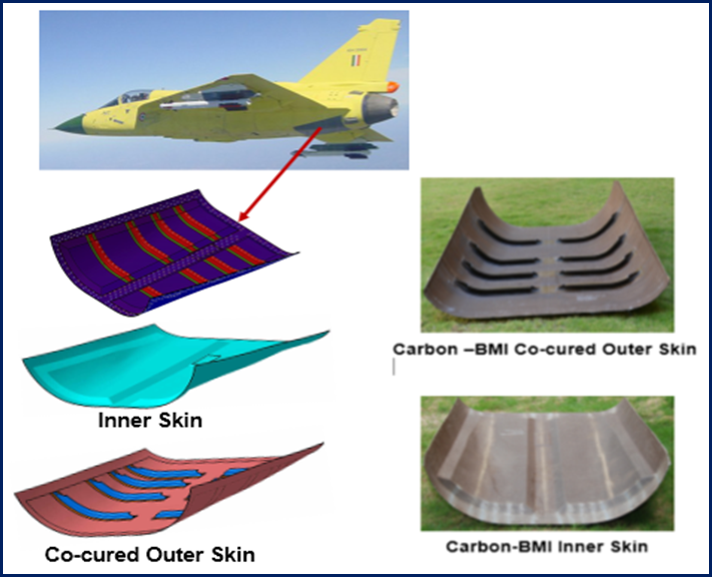

Structural Assembly of Cocured Composite Parts

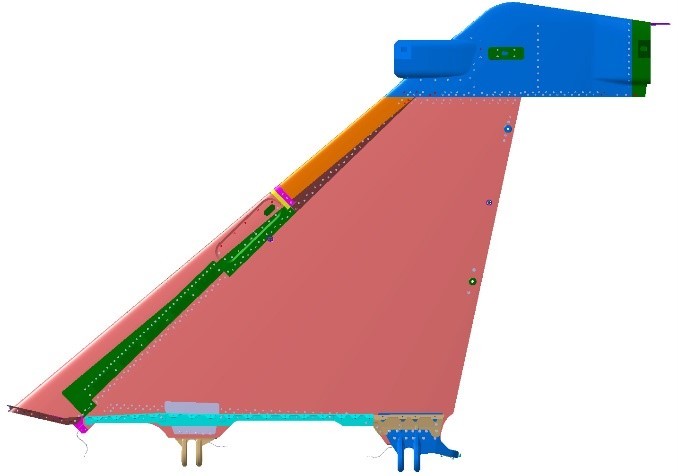

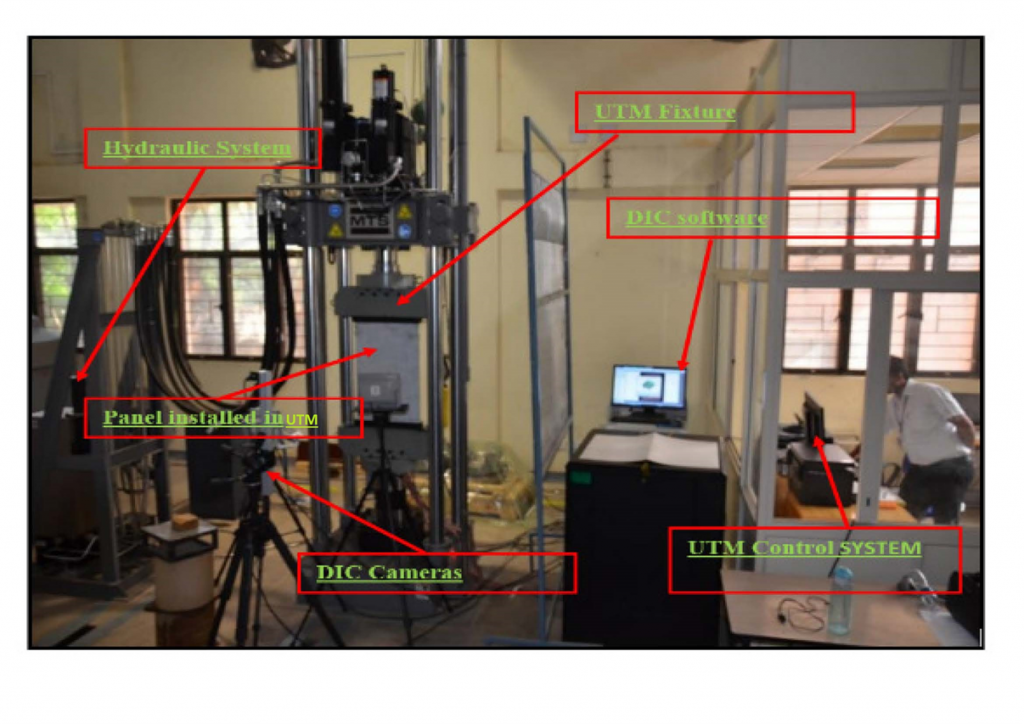

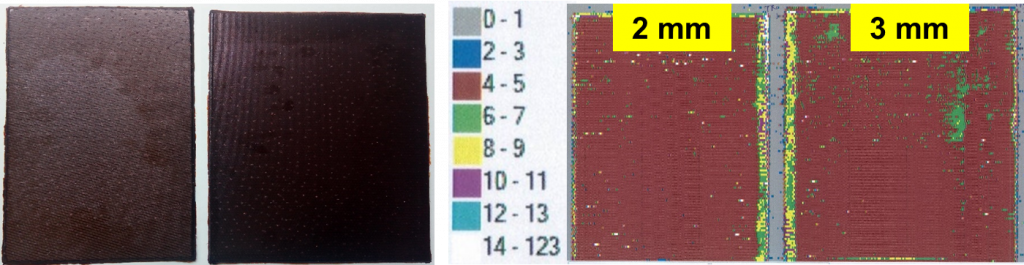

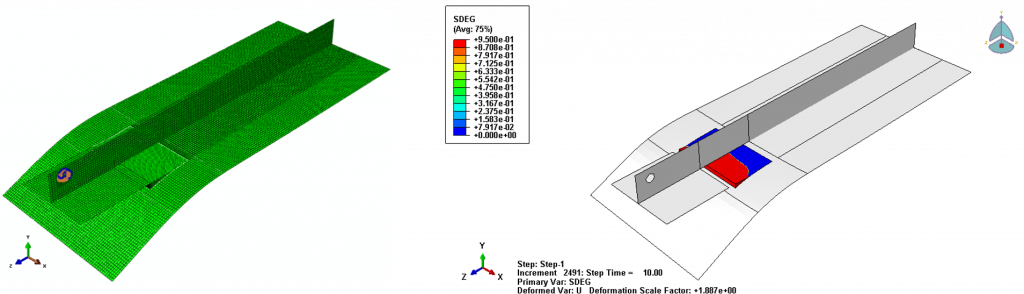

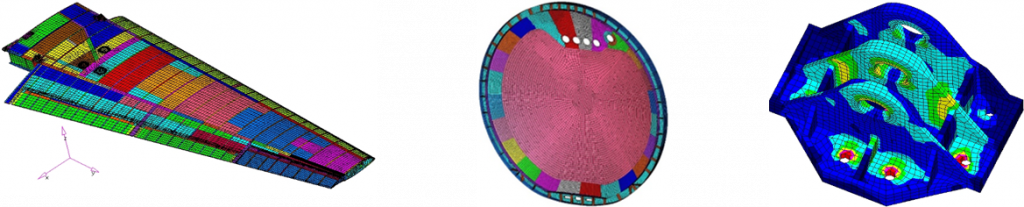

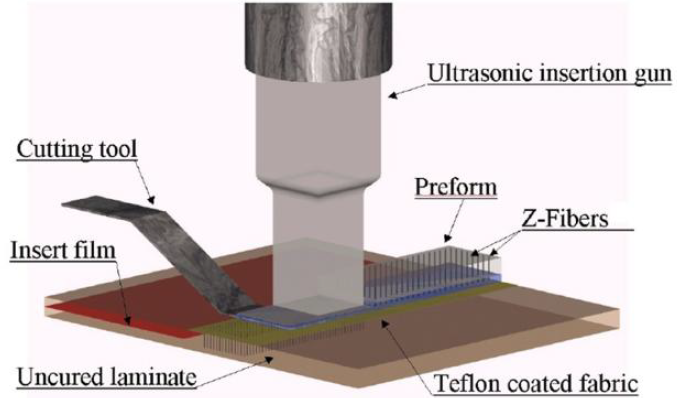

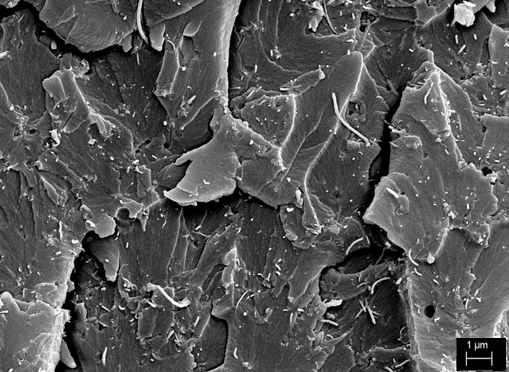

Manufacturing aircraft composite components requires maximum precision and quality in all process steps including the assembly of subcomponents. Major fully integrated co-cured composite components are assembled with sub-assemblies to realise major structural assembly of an Aircraft. Advanced Composites division is equipped with necessary infrastructure and facilities. Expertise is available to design & develop part locators, trimming and drilling fixtures to meet aeronautical standards.

ACD has rich experience in both metallic & composite aircraft structural assemblies for military and civil aircraft applications. The structural assembly includes putting together the major components such as the ailerons, elevators, rudder, flaps, nacelles, landing gear, wing sections, etc. Experience in (i) assembling interchangeability parts like all control surfaces (ii) drilling, reaming and countersunk operations in composite laminates/ hybrid laminates without any damage and delaminations utilizing hand-powered tools. Knowledge of integral fuel tank sealing processes and usages of interlay sealant and structural adhesives.

English

English हिन्दी

हिन्दी