Detailed Design

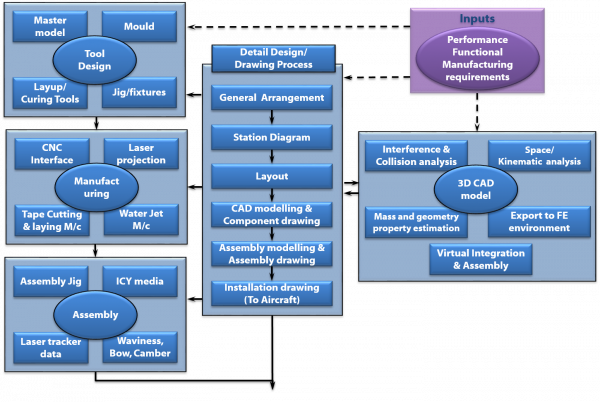

Detail Design acts as a focal point and provides comprehensive solutions for the product development from conceptual-to-component assembly. It has exhaustive capabilities for specifying detailed component geometry in support of inputs from the stress group, synthesizing the requirements into a producible one, and fulfilling the conflicting requirements from the tooling, manufacturing & assembly in the process of product development. However, the detail designer must first map the requirements and mentally visualize the physical object, and convert into functional specification with layout design before the detailed geometric design in CAD, as it involves often more creative steps, innovative thinking and collaborative interactions. The different stages of activities as follows,

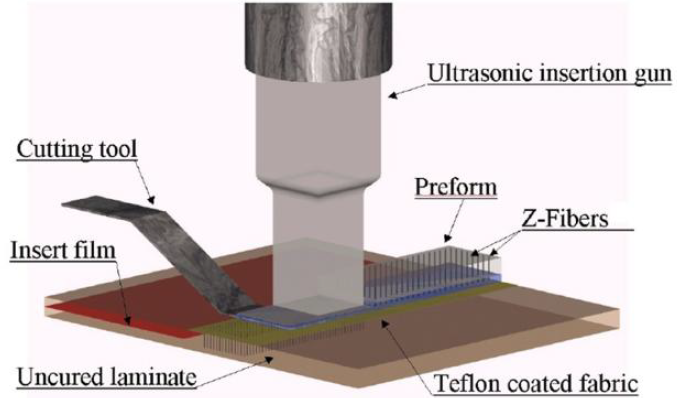

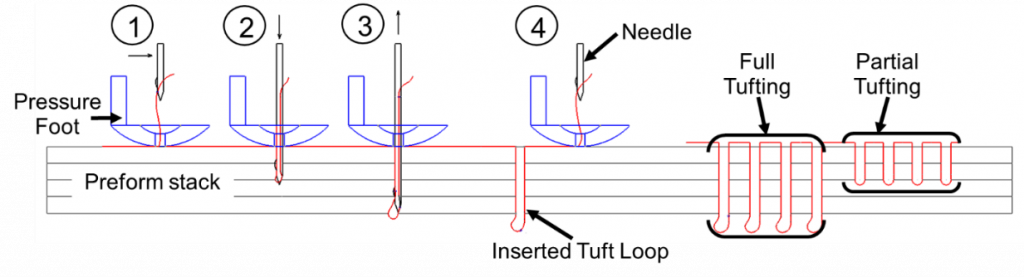

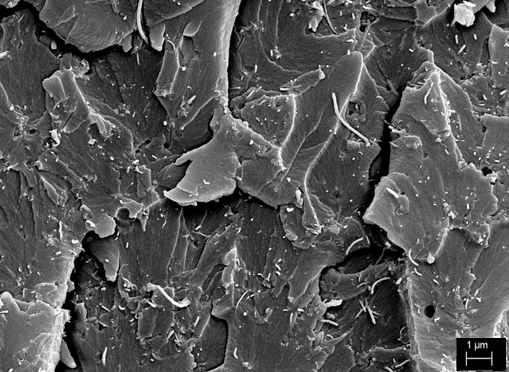

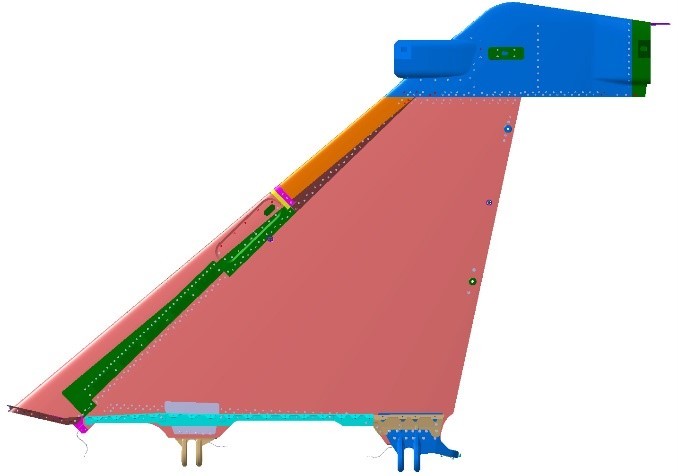

- Layout design is evolved after the station diagram (2D & 3D) generation with top-down approach wherein the functional representations such as Numerical Master Geometry (NMG), Interchangeability (ICY) points and Kinematic positions of moving parts are defined to meet the requirements. The geometry (component shape, size, station locations, ply details for composite parts & thickness distribution, joints, etc.), material and standard part specifications are comprehensively defined in the layout.

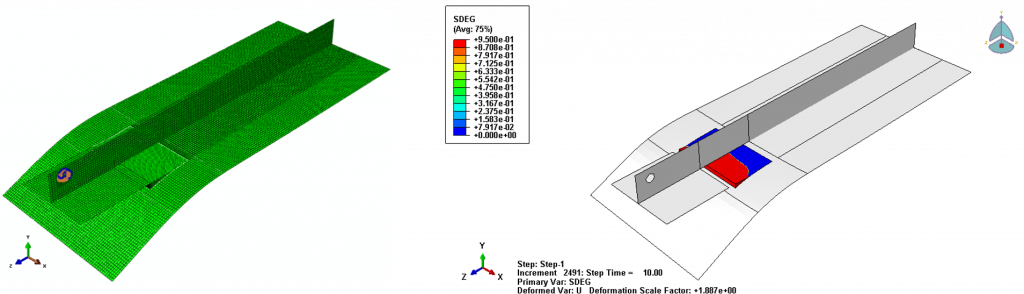

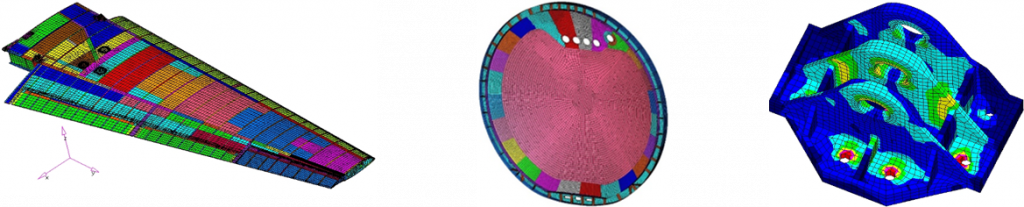

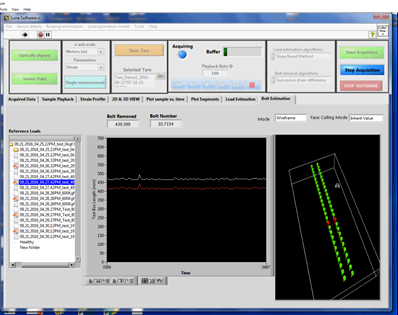

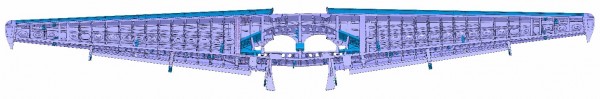

- The 3D CAD model of the components including standard parts are accurately created from the preliminary geometry specifications, for which the input data are extracted from the layout. The 3D CAD modeling enables the designer to generate multi-views, to enable the visualization, to extract the mass properties and to perform the assembly simulation. It also supports the downstream design and digital manufacturing activities such as finite element analysis, 3D printing, waterjet cutting, laser projection, process planning, NC code generation, etc.

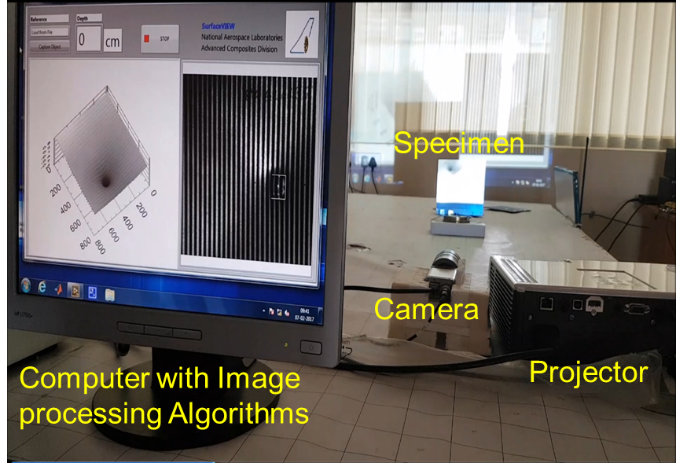

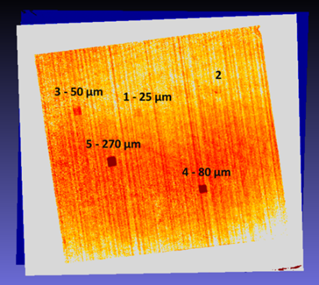

- Detailing and 2D production standard drawings are generated from the CAD models wherein the details such as geometry, dimensions, tolerances, material, process, layup stacking sequence in case of composite parts, NDT, finish, etc. are provided precisely to ease and successfully carryout the further activities viz., manufacturing, assembly, inspection, etc.

- The hierarchical assembly model is created to satisfy the functional constraints and the assembly relationship of mating parts, which includes clash analysis, kinematic simulations, space analysis and fastener installation checks. Product Lifecycle Management has been successfully implemented to connect with the production data server that addresses the complete lifecycle issues of the product.

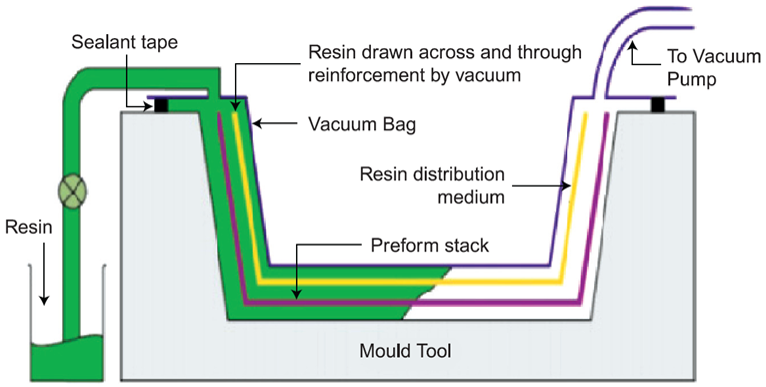

- For tooling & manufacturing, the team is relentlessly supporting the tool design and providing the data for making many elements in tooling such as master model, mould, internal tools, layup & curing tools and other allied tools. Team is extensively associated with manufacturing related activities by providing data for tape cutting, laser projection, transfer foils, various check templates, etc. Contour/surface deviation analysis carried out w.r.t CAD geometry for the manufactured and assembled components.

Detail Design Solutions: Conceptual-to-Component Assembly

Specifications

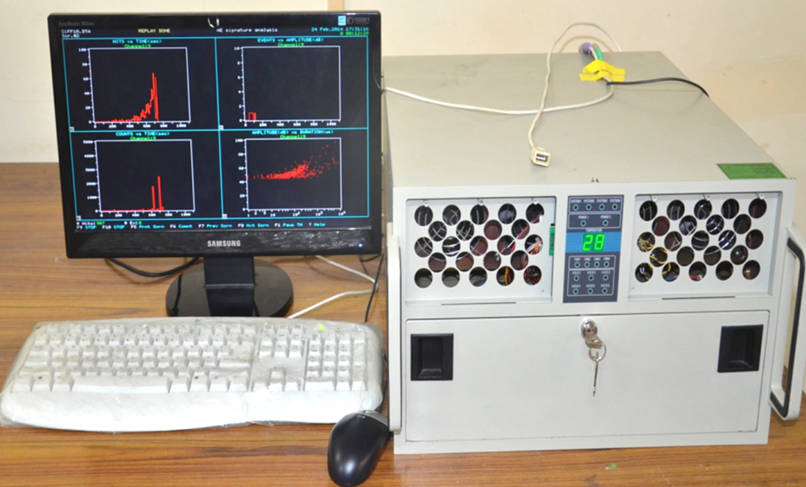

The State-of-the-art CADD Center is equipped with highly sophisticated server, workstations and storage device for efficiently handling the advanced software and large volume of design data more than a Lakh hard and soft formats (drawings, models, design data). CADD Center is secured with stringent and seamless data transfer facility within/outside the team, and is enriched with redundant data backup.

|

CAD Software |

3D CAD modeling |

CATIA V4, V5 & V6 |

|

|

2D drawing/ Detailing |

AutoCAD |

||

|

Data management/ |

3DExperience |

ACD CADD CENTER

Major milestones / results of this technique

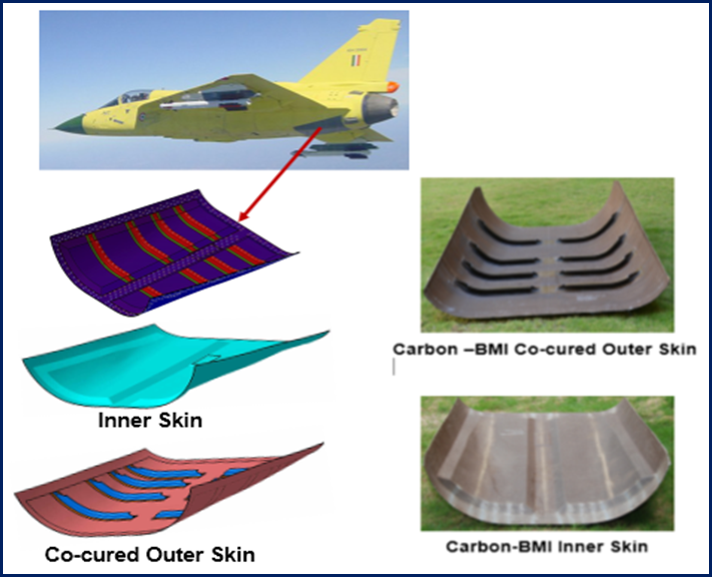

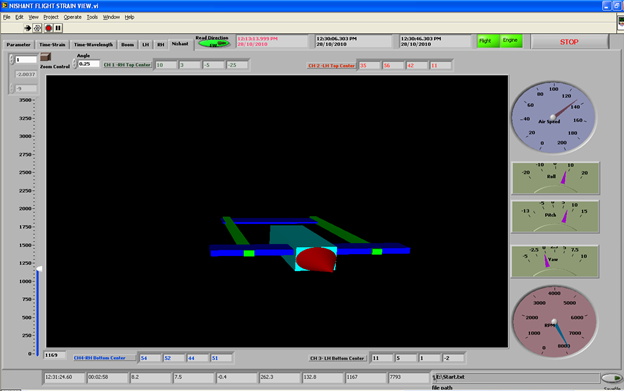

The detail design team has successfully completed and continued to support for the different major aircraft programs like TEJAS & SARAS aircrafts and Recovery of an UAV.

SARAS Composite Wing

English

English हिन्दी

हिन्दी