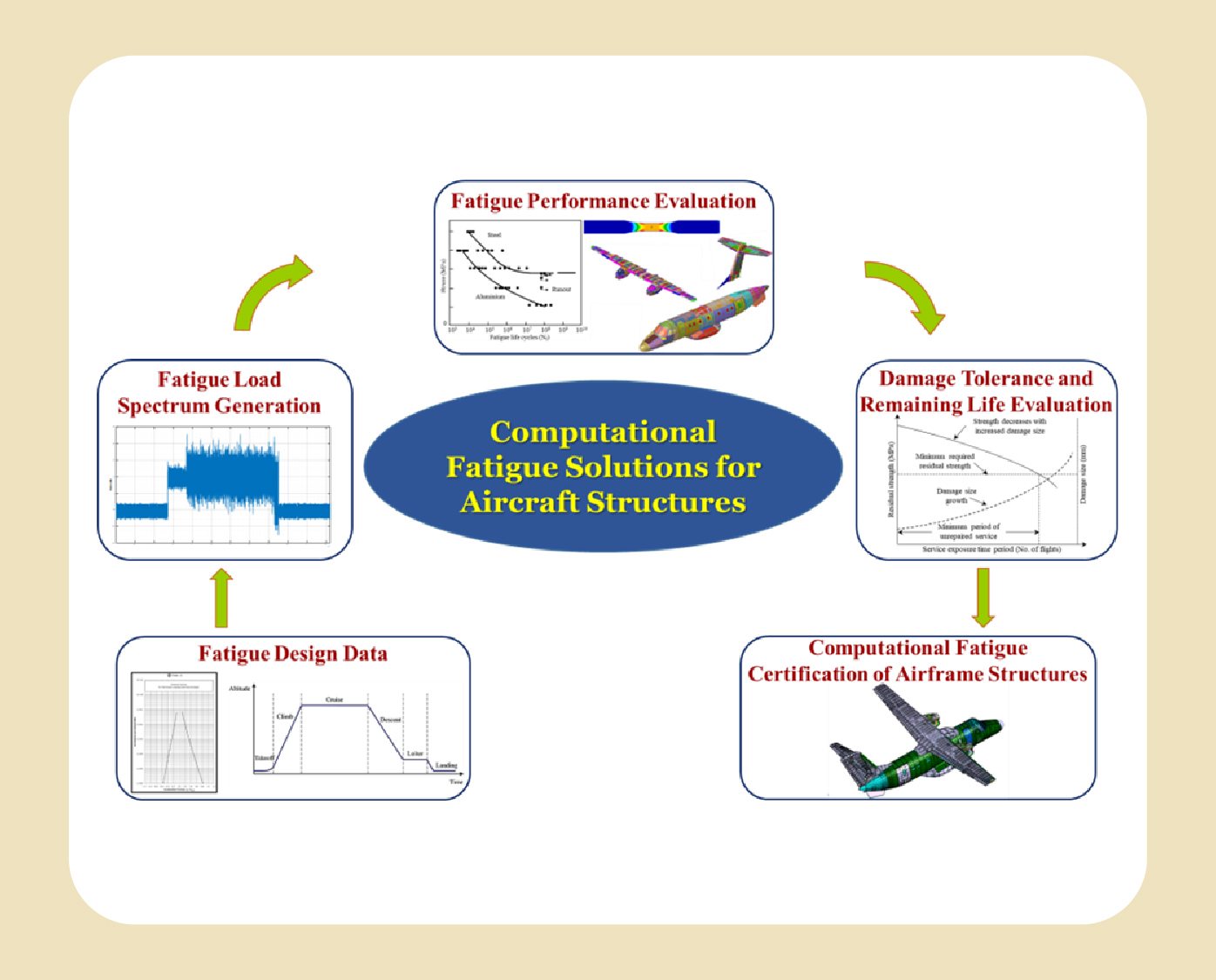

Unlocking the Potential of our Facilities

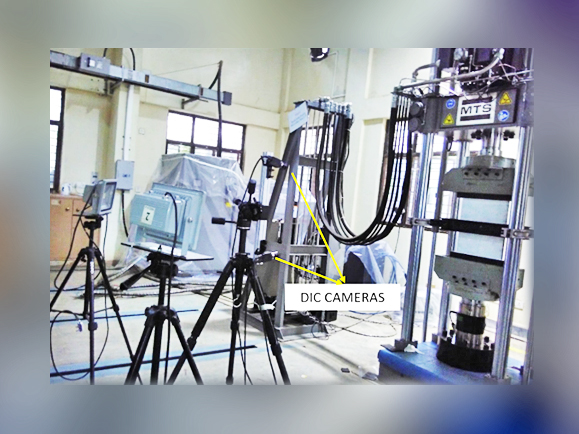

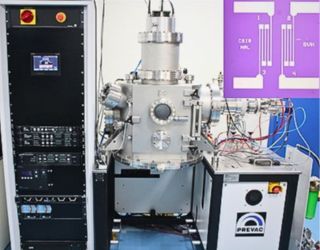

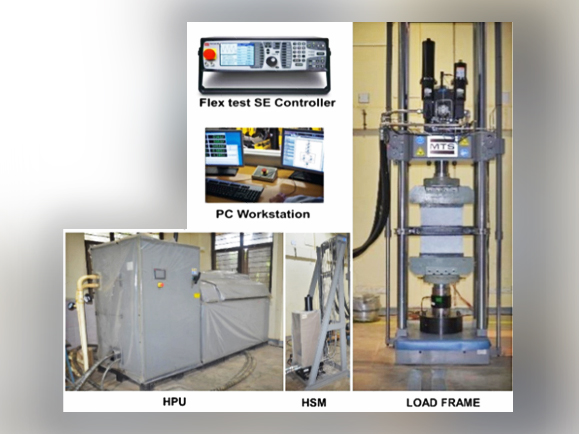

CSIR-NAL offers a diverse range of facilities dedicated to aerospace research and development, including state-of-the-art testing facilities, wind tunnels, and specialized laboratories focused on electromagnetics and aerodynamics.