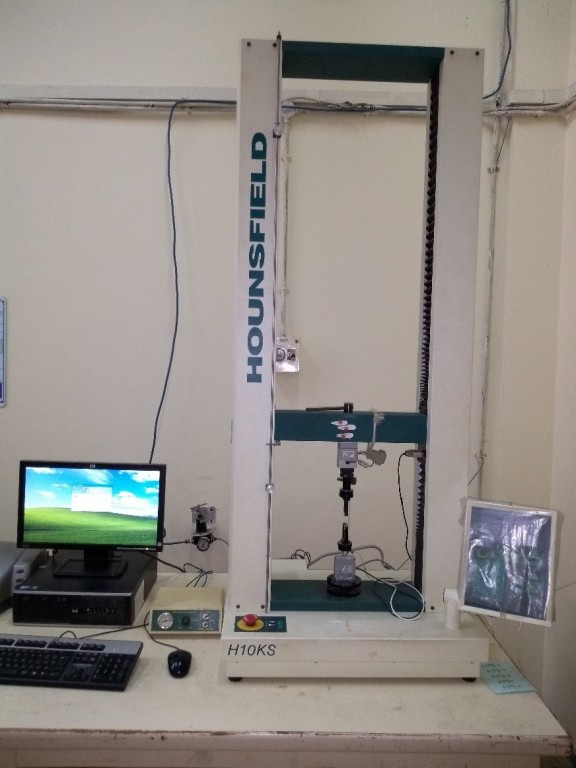

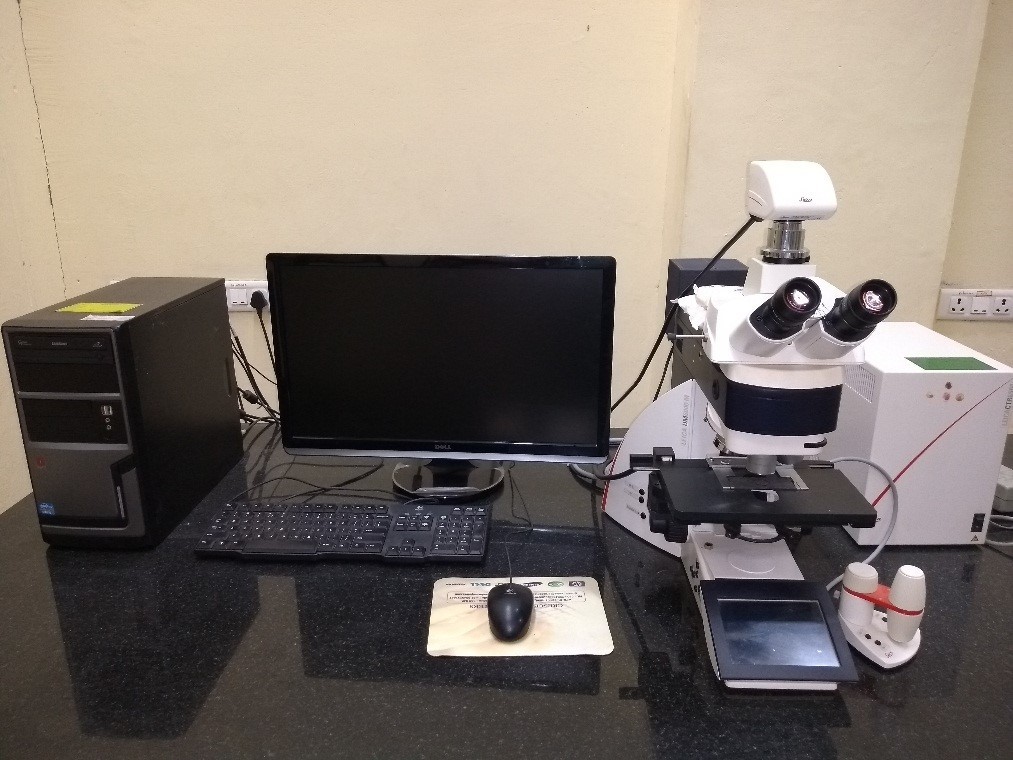

Carbon fiber is a high strength, high-stiffness and low weight material, used extensively in aircraft, missiles, launch vehicles and satellites. It is also an important raw material in many vital industrial applications such as wind energy, infrastructure, sports and transportation, to name a few.

CSIR-NAL established an integrated facility for carbon fiber and prepregs in 2003 with the focus on indigenizing the carbon fiber development from polyacrylonitrile based precursor fiber. As an outcome of the developmental efforts NAL entered into an MoU with M/s Kemrock Industrial Exports Ltd, Vadodara for sharing process know-how and offering technical assistance in the setting up of 300 TPA standard modulus carbon fiber plant at Vadodara. Kemrock commissioned India’s first commercial scale carbon fiber manufacturing facility and it became completely operationalized in 2011 with type certified by CEMILAC for standard modulus grade carbon fiber production.

Meanwhile, the centre was involved in development of intermediate modulus carbon fibers and incorporated necessary equipment modifications. During this period, MIDHANI, Hyderabad financially assisted NAL in developing an improved process technology for standard modulus carbon fibers, which were certified in 2017 by CEMILAC. Subsequent to this NAL has been contacted by many firms including RIL for transferring the process know-how.

Currently, the centre is involved in the development of intermediate modulus carbon fibers and also undertaking a feasibility study on low cost alternative precursors for carbon fibers with possible benefits on environmental management. The centre envisages a greater role in process know-how transfer and technical consultancy against the backdrop of growing interest in setting up carbon fiber plants to cater to the need of composite industries.

English

English हिन्दी

हिन्दी