Carbonization and graphitization technique

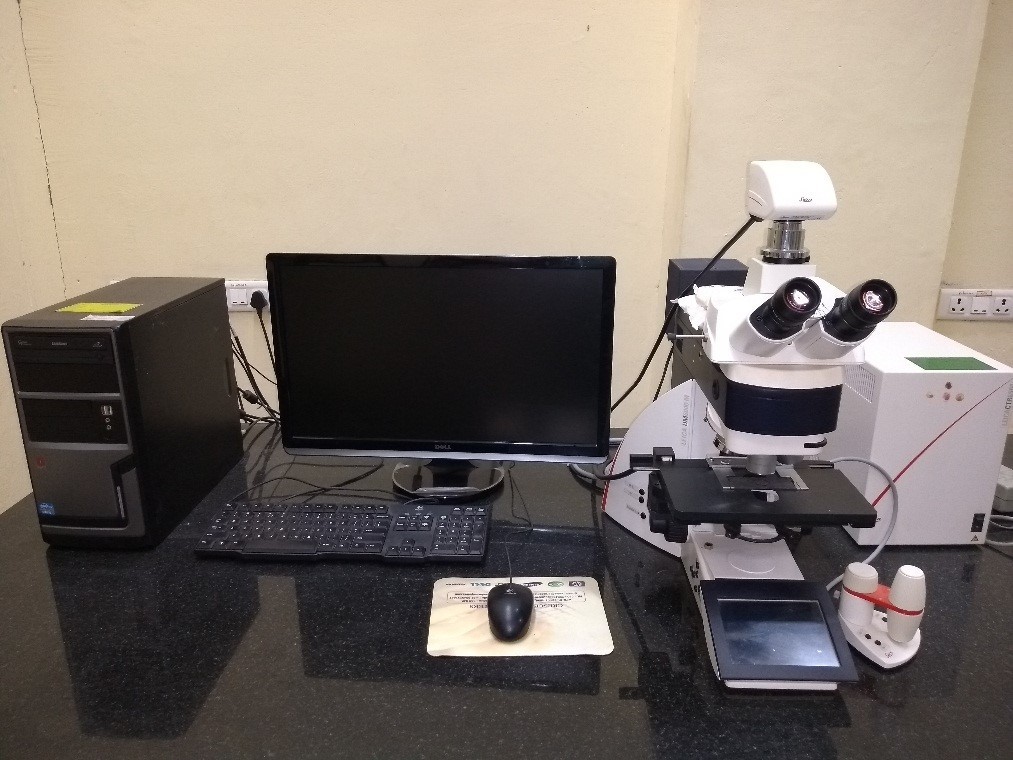

The carbonization processes are preceded by thermo-oxidative stabilization in the heat treatment line for the continuous conversion of acrylic precursor fibers into carbon fibers. The conversion process under inert atmosphere is carried out in two stages; pre-carbonization and carbonization. The pre-carbonization process is done in an open, slotted muffle low temperature furnace at up to 850oC in a controlled temperature profile to facilitate gradual evolution of gaseous effluents. The volatiles are exhausted after passing through an incinerator. The pre-carbonized fibers are then carbonized by introducing into an open, graphite muffle furnace with temperature upto 1350oC. The carbon fibers with required level of carbon content and a combination of mechanical properties are obtained by altering the carbonization process conditions. For achieving high modulus, an optional graphitization process is done in a graphite furnace upto 2400oC. The carbonized/graphitized fibers are then forwarded to surface treatment unit.

Specifications

No. of tows: 40

Line speed: up to 1.5 m/min

Facilities where this technique is used: Fiber heat treatment facility (F3)

Major mile stones / results of this technique : Certification for standard modulus grade carbon fibers

English

English हिन्दी

हिन्दी