Aqueous slurry polymerization technique

Aqueous slurry polymerization is the most widely adopted techniques/process for acrylic fiber manufacturing. Water is used here as a continuous phase of the system. The monomer acrylonitrile along with the desired co-monomer (usually methacrylic acid, itaconic acid, methyl acrylate etc.) are copolymerized by free radical polymerization mechanism. The monomer, co-monomer, initiator, activator and a chain transfer agent continuously fed to the continuous stirred tank reactor (CSTR) under controlled pH. The polymerization reaction progress through initiation, propagation and termination steps of radicals and precipitated polymer particles forms a slurry. The polymer slurry is continuously removed from the reactor by overflow line and sent for downstream operation. To ensure complete termination of the reaction, external terminator is added to the slurry.

Specifications

Polymer production capacity : 12-25 kg/hr

pH of reaction: 2.5-3.0

Polymer inherent viscosity: 1.5-4.0 dl/g

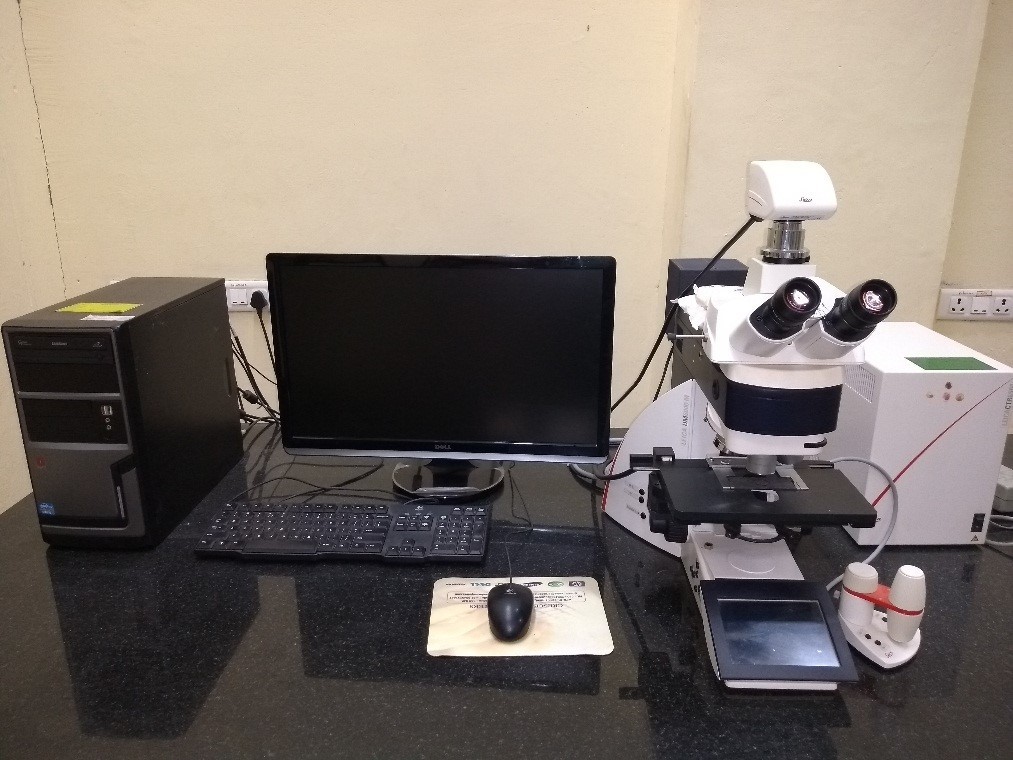

Facilities where this technique is used : Acrylonitrile polymerization facility (F1)

Major mile stones / results of this technique:

English

English हिन्दी

हिन्दी