RHEOMETRIC ANALYSIS

Rheometric analysis generally refers to experimental techniques used to determine the flow behavior and deformation of a material, i.e. the quantitative and qualitative relationships between deformations and stresses and their derivatives. The rheometric analysis at CCFP are done by:

- Brookfield viscometer

- Rheometer

- Brookfield viscometer

This employs the principle of rotational viscometry. The torque required to turn a spindle in a fluid indicates the viscosity of the fluid. Torque is applied through a calibrated spring to the spindle immersed in the test liquid and the spring deflection measures the viscous drag of the fluid against the spindle. Depending upon the thickness of the solution the spindle is chosen. The Brookfield viscometer model “HADV I+” and “DV1” is used at CCFP. Labelled as LV or RV spindle sets, these comprise simple shafts ending in a disk or cylinder. A sample of 400 - 600ml in a suitable container is placed under the viscometer which is then lowered to dip the spindle into the sample up to an immersion mark on the spindle shaft. The temperature is noted down prior to measurement.

Facilities where this technique is used:

The viscosity of the concentrated polymer solution (prepared for spinning) at different temperatures are measured. The viscosity gives a fair idea about the spinnability as well as the concentrations of the polymer solution. The viscosity of the sizing as well as the spin finish solution is determined by this technique.

- Rheometer

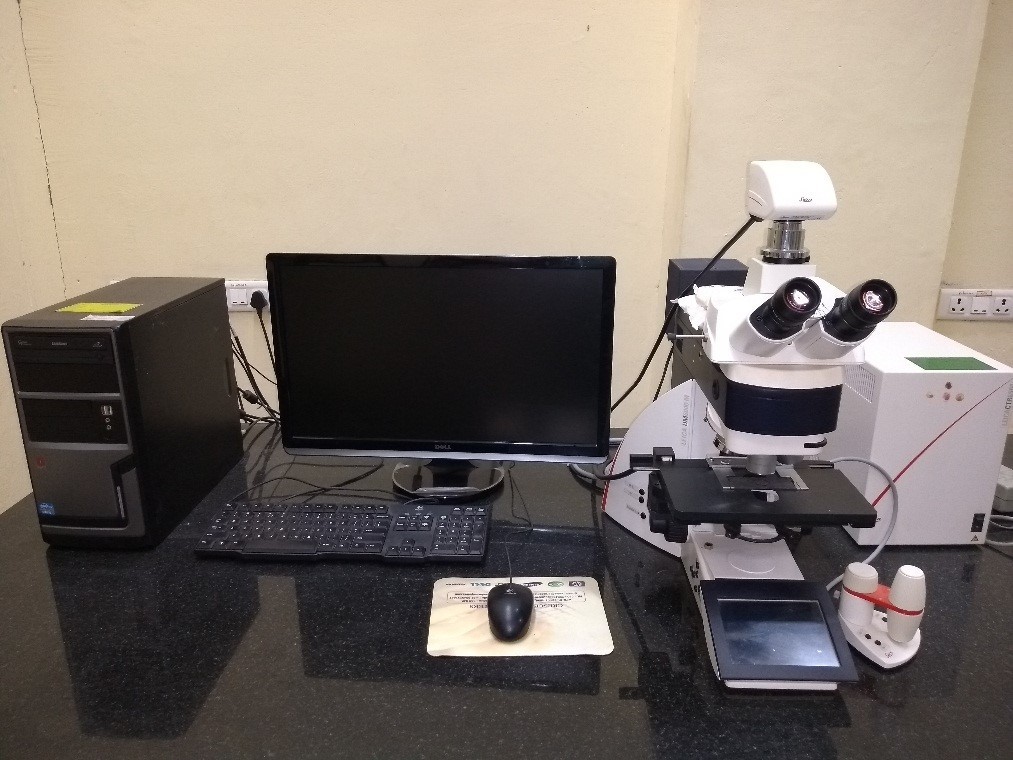

A rheometer is a precision instrument that contains the material of interest in a geometric configuration, controls the environment around it, and applies and measures wide ranges of stress, strain, and strain rate. At CCFP we have “Anton Paar model MCR102” rheometer. It consists of

- Environment chamber (-150oC C to 600oC)

- Parallel plate geometry

- DMTA holder for solid and film samples

- Air filter

- Temperature control unit

- Water cooler unit (-100C minimum)

Computer for Data acquisition

Computer for Data acquisition

Facilities where this technique is used:

The rheological characteristics of the dope at different temperature is studied. The relaxation time, gel time, storage modulus and loss modulus and other phenomena which are crucial for dope characteristics are studied critically. The gel time of the resin system used for fiber coatings are also studied.

English

English हिन्दी

हिन्दी