MECHANICAL PROPERTIES

The mechanical properties of a material are those properties that involve a reaction to an applied load. Mechanical properties are also used to help classify and identify material. The most common properties considered are strength, ductility, hardness, impact resistance, and fracture toughness. The mechanical properties of a material are not constants and often change as a function of temperature, rate of loading, and other conditions. It should also be noted that there is often significant variability in the values obtained when measuring mechanical properties. Seemingly identical test specimen from the same lot of material will often produce considerable different results. Therefore, multiple tests are commonly conducted to determine mechanical properties and values reported can be an average value or calculated statistical minimum value. Also, a range of values are sometimes reported in order to show variability. The mechanical properties are measured by the following equipment at CCFP:

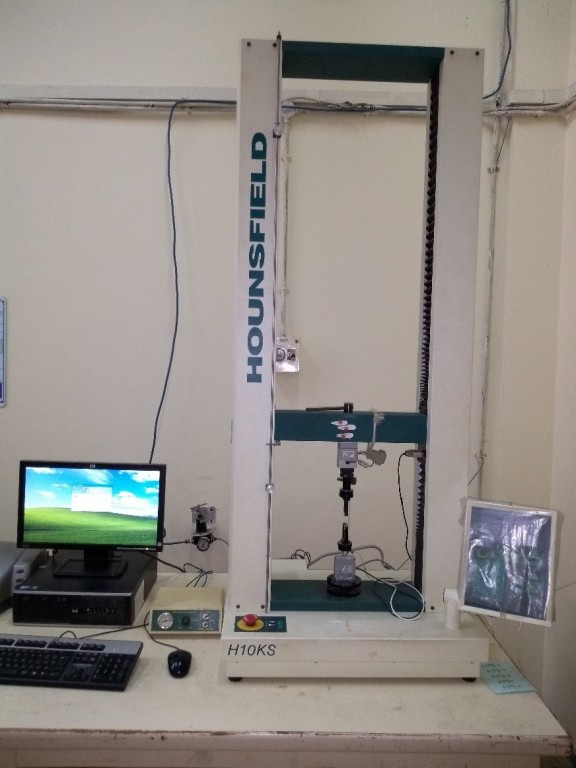

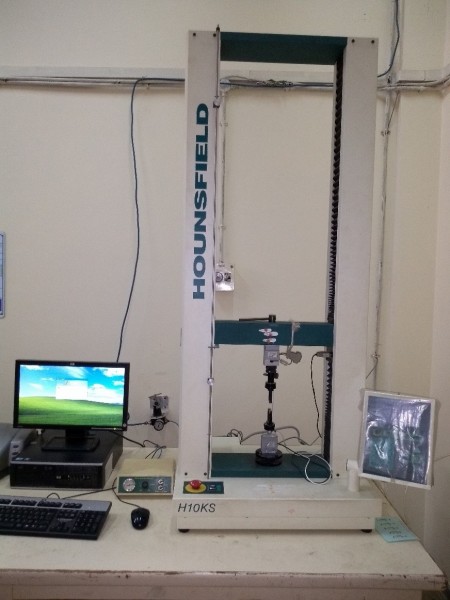

- Universal testing machine

- Instron

- Universal testing machine

A table top model “H10KS” UTM machine by tinius olsen is used to determine the tensile properties of fiber. It has different load cells from 5000 N to 5 N. Depending upon the fiber to be tested the load cell and the cross head speed are fixed. The grip used to hold the fiber also varies. For single filament testing pneumatic grips are used.

Facilities where this technique is used:

The single filament tensile properties of special acrylic fiber, various heat treated fiber and the carbon fiber is determined. The dry yarn strength of the acrylic fiber and other fibers are also determined.

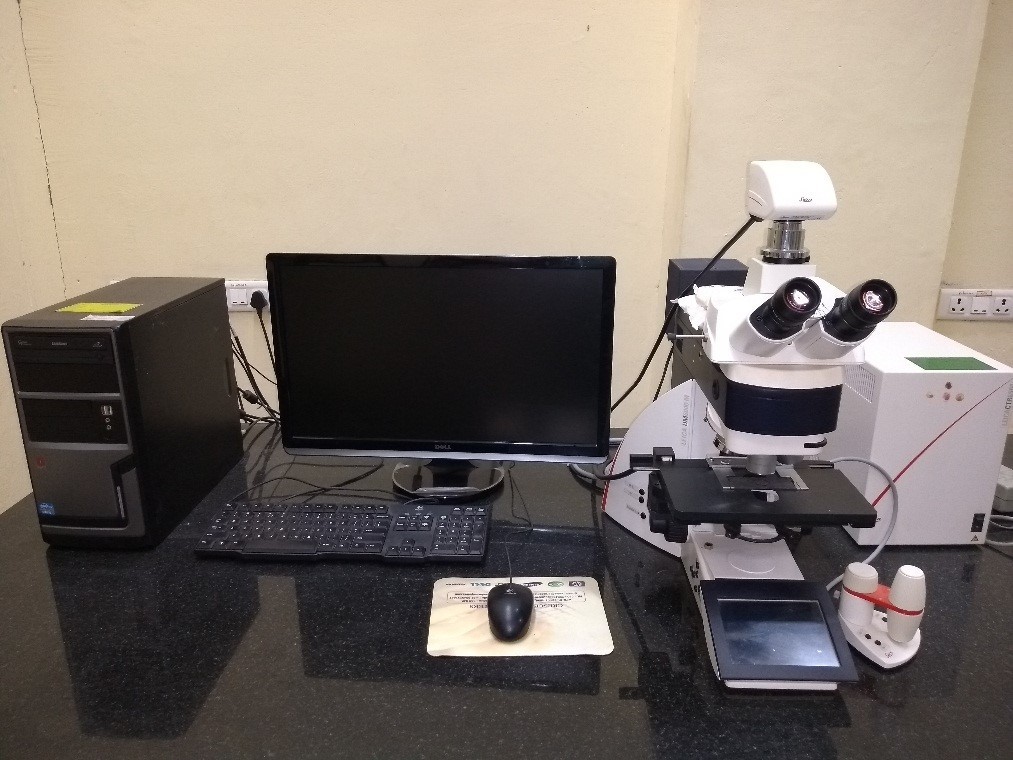

- Instron

The Instron model “5500R” is used to determine the mechanical properties of the impregnated tows and composites. The load cell used, the cross head speed, the gauge length and the testing jigs vary with the samples type as well as the geometry.

Facilities where this technique is used: Fiber spinning facility (F2), Fiber heat treatment facility (F3).

This is used to determine the tow strength of the resin impregnated carbon fiber which is very crucial. The mechanical properties like flexural strength, compressive strength etc. of the composites have also been tested.

English

English हिन्दी

हिन्दी