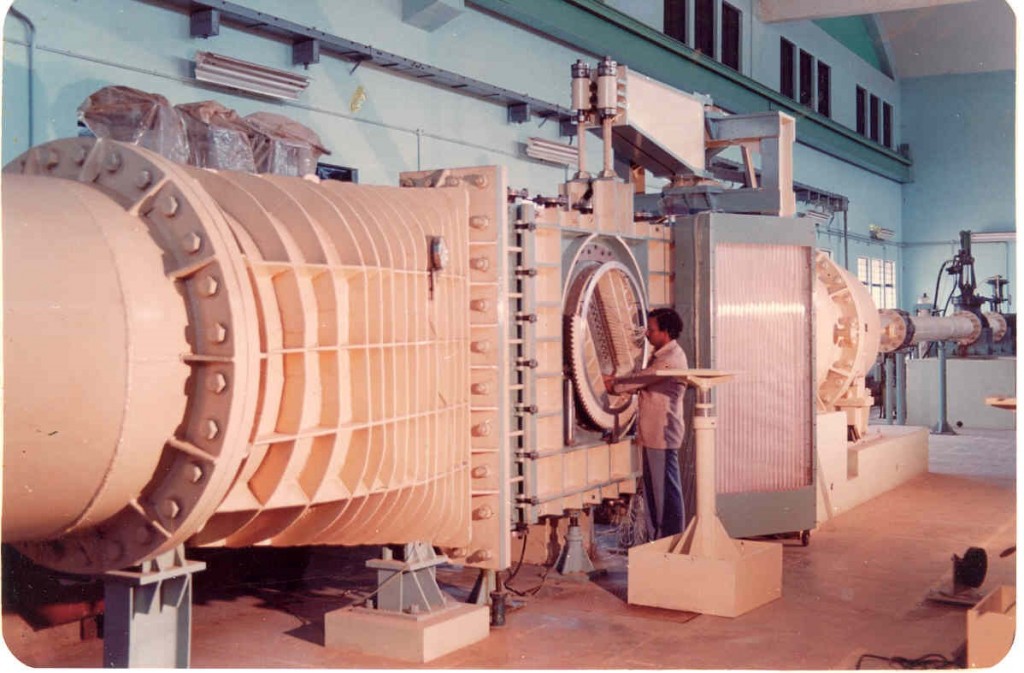

High Speed Alternator Test Facility

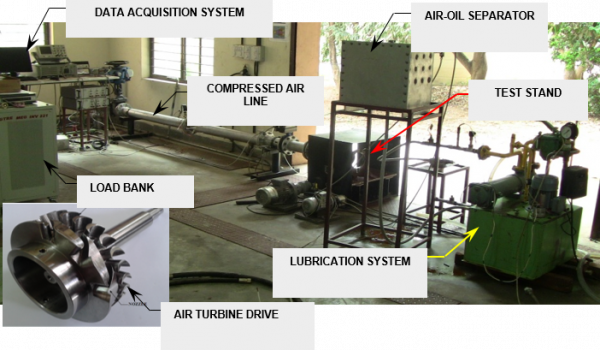

Technology demonstration of a high speed alternator was done successfully for 4.5 kW Power at 30000 rpm for a small gas turbine engine. Alternator and air turbine drive set up was made in-house. A small turbofan engine high speed homopolar alternator was also successfully tested in this facility.

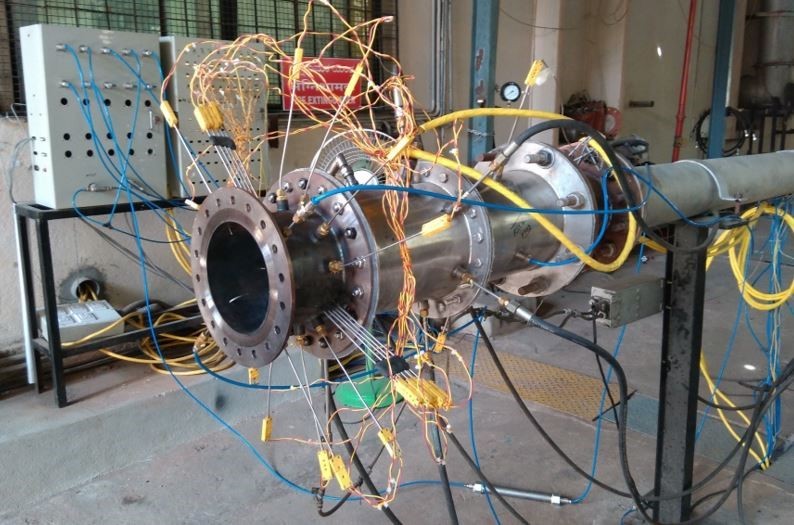

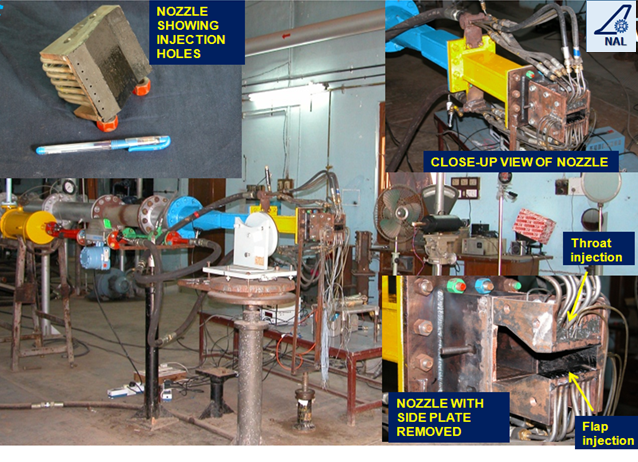

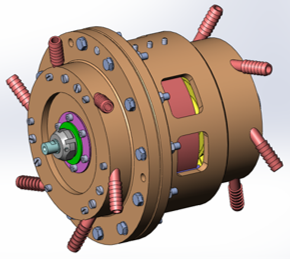

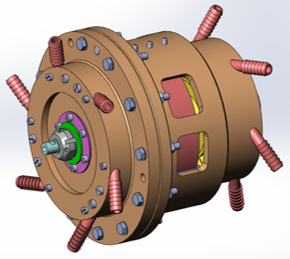

Alternator test rig Model Alternator test rig

Salient features;

-

An Air turbine drives stage for 20kW Power at 60000 rpm.

-

A dedicated lubrication system for alternator cooling requirement.

-

Electrical measurements and controls and in house data acquisition application modules.

Techniques:

- Permanent Magnet Rotors.

Clients: DRDO-GTRE, Bangalore

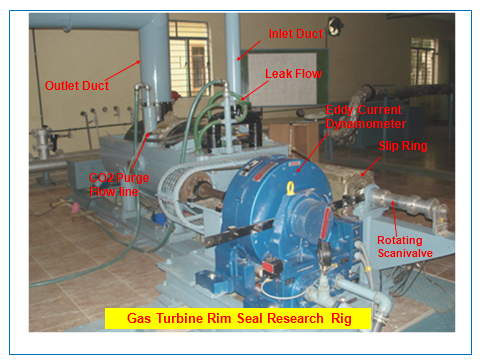

FACILITY 2: Vapour Compression Refrigeration System Test Rig

Vapour compression refrigeration system test rig is utilized to generate the design data for compact plate fin type condenser and evaporator test cores.

Vapour Compression Refrigeration System Test Rig

Specifications

Refrigeration Capacity : 10 tons,

Mass Flow rate : 0.1 kg/s

Pressure : 20 Bar

Medium : R134A

Major clients of this facility

ADA- Bangalore and GTRE Bangalore,

English

English हिन्दी

हिन्दी