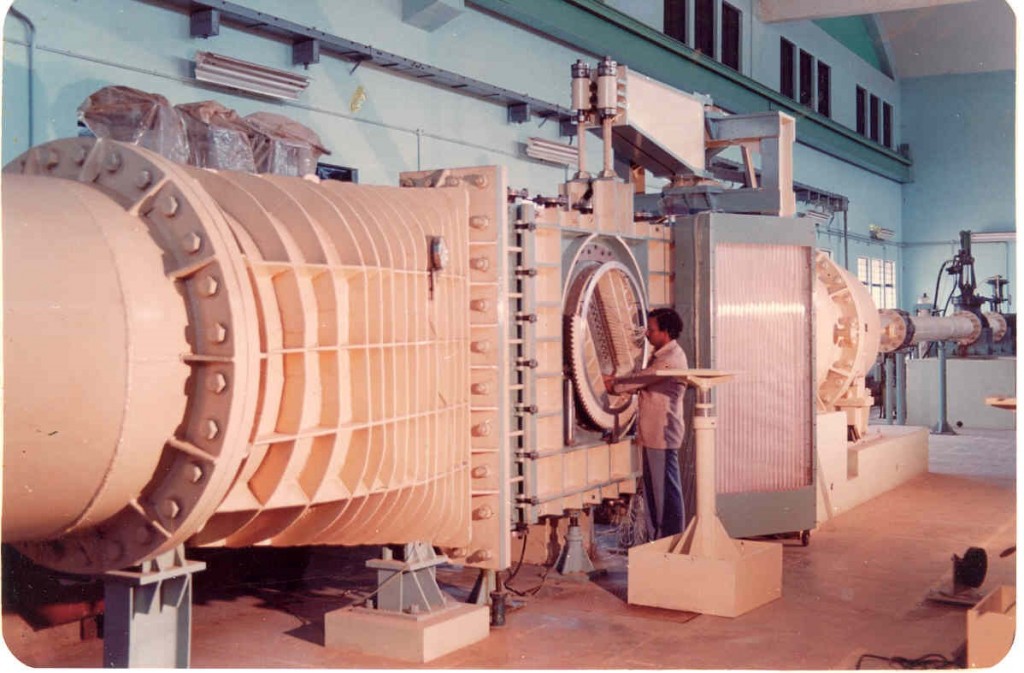

Small Gas Turbine Engine Test (GET) Facility

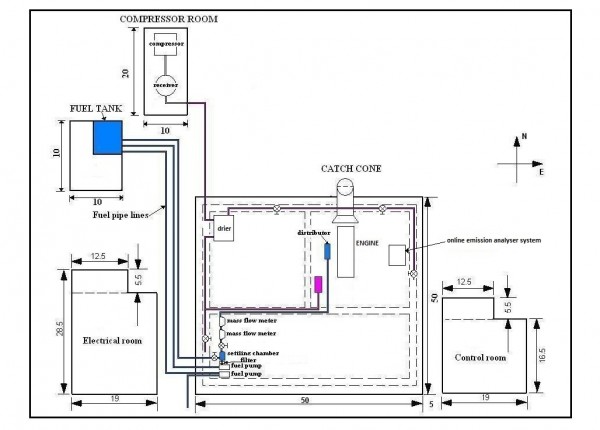

Small Gas Turbine Engine Test (GET) Facility has been developed for testing small gas turbine engine producing thrust upto 500 kgf. It contains test bay, control room, compressor room, electrical room and fuel tank.

The test bay can accommodate two engines with sufficient frontal space. The control and display units for different instruments, throttle, CCTV and NI system for data acquisition are placed in the control room. Fuel tank having capacity of 1000 liter is placed at the height of 11 feet to store the fuel.

Fig 1: Plan of GET Facility

GET facility is equipped with the following systems:

1. Fuel line system: It contains fuel tank, pipe lines, pump, mass flow meter, engine and a bypass pipe line. It is capable to pump the fuel from the fuel tank to the engine at a pressure upto 50 psig.

2. Airline system: It contains two compressors, a 35 kg/cm2 high pressure compressor with receiver tank and a 7 kg/cm2 low pressure compressor with receiver tank and air dryer.

3. Lubricating Oil system: It has a 40 litre tank and 1 hp pump capable of pumping oil to the engine for lubrication.

4. Engine Exhaust System: Exhaust system is capable of throwing out the hot exhaust gas outside the test cell at the rate of 6.25 kg/s to the atmosphere. The diameter of the exhaust duct is 600 mm.

5. Emission Analyzer system: It is capable of measuring the different species like CO2, O2, CO, NOx and unburnt hydrocarbons in the exhaust gas going to the atmosphere. It indicates the quality of combustion and ensures the requirements for environmental safety, if any.

6. Smoke meter: Smoke meter makes measurements in the smoke It operates at a temperature range of 10 - 50 °C.

7. Ground Power Unit (GPU): It receives 3 phase input @ 420V ±10%, 50Hz and provides DC power at 30V, 800A. It is used to provide power to electric starter which engages with the main engine shaft and runs the turbine to generate power.

8. Data Acquisition System

Data acquisition system consists of sensors and DAQ cards.

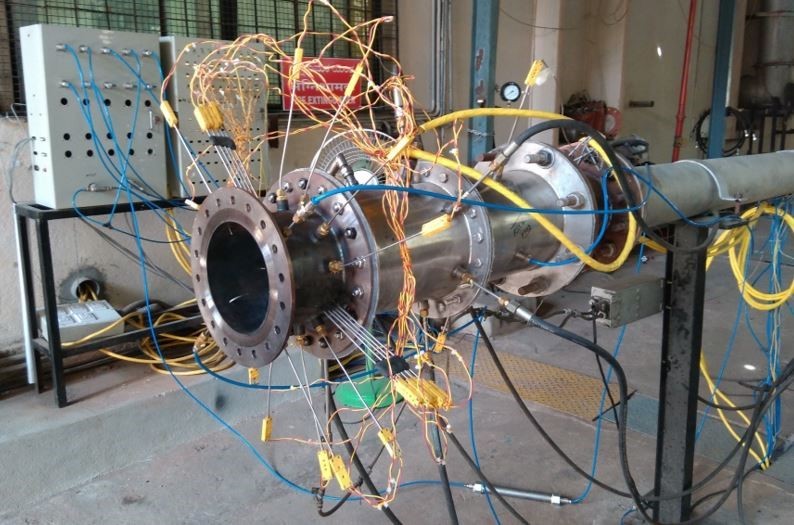

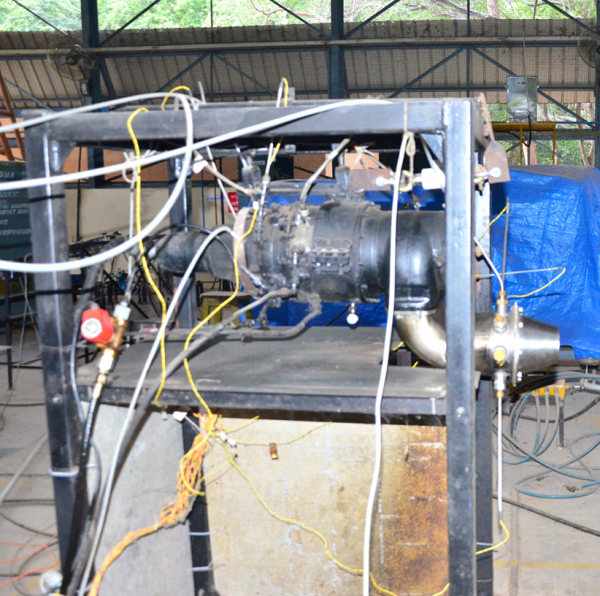

Fig 2: Engine mounted on test stand.

English

English हिन्दी

हिन्दी