Damage Tolerance Testing

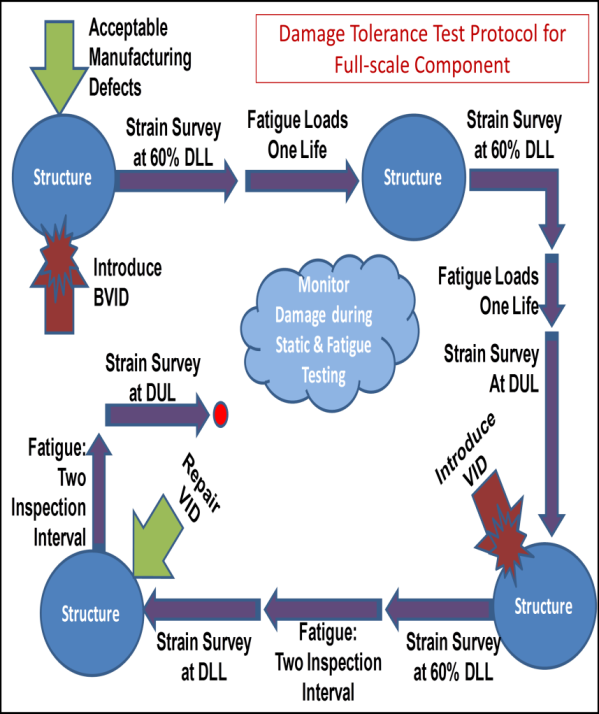

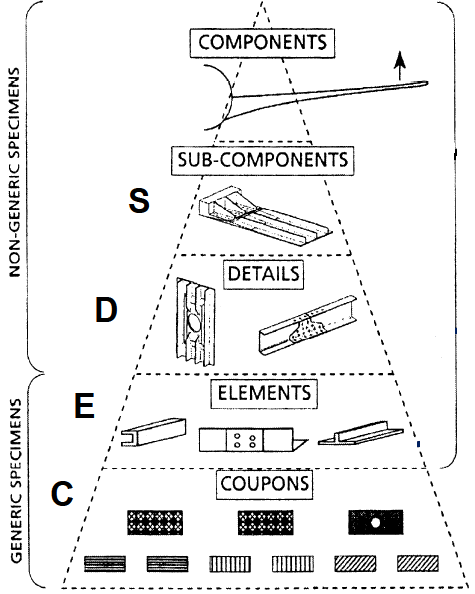

Certification demand for damage tolerant design of structures has fuelled the ‘Damage tolerance studies’ on composite structures in the division. Studies in testing and simulation for certification of composite structures meeting the damage tolerant requirements are executed in the division. The DT group has the expertise to develop test protocols apart from conducting tests and analyses methodology on various coupons, elements, details, sub-components and components across the building-block pyramid to demonstrate compliance to airworthiness requirements such as FAR 25.571.

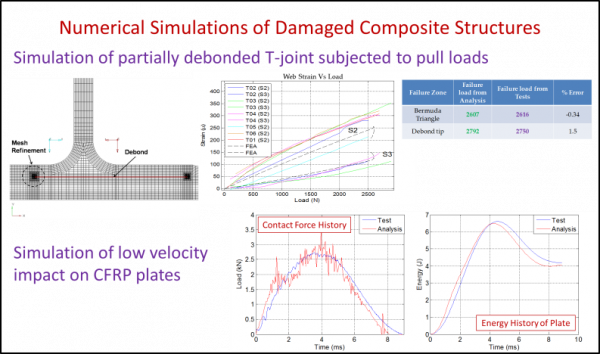

The division has the following facilities and capabilities: (1) Portable drop tower for low velocity impact tests, (2) State-of-art NDI techniques, (3) 150kN Universal Testing Machine for coupon tests, (4) 1000kN servo-controlled UTM for conducting static and fatigue tests on large panels and specimens, (5) Servo-hydraulic multi-actuator systems for static & fatigue testing, (6) Digital Image Correlation (DIC) facility for full-field displacement & strain measurements, and (7) State-of-the-art computational facility for numerical computations.

|

ding Block Approach to Certify Primary Aircraft Structures |

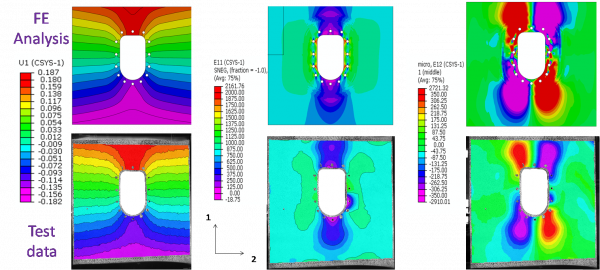

Sample Study at Detail Level: Composite Panels Representing a Typical Aircraft Wing Skin |

||

|

|

||

|

Development of Numerical Models & Validation through Full-field Measurements During Tests

|

|||

|

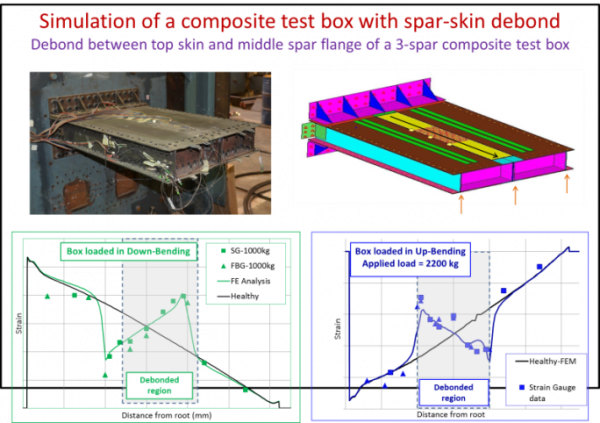

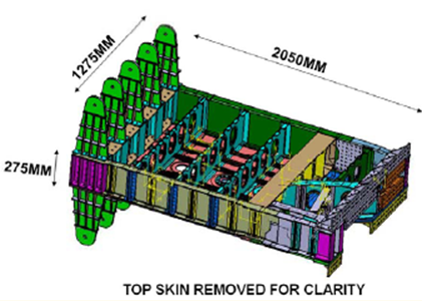

Sample Study at Sub-component Level: Composite Wing Test Box |

|||

|

|

|

||

|

|

|

||

English

English हिन्दी

हिन्दी