Non-destructive Evaluation & Testing

Non-destructive Evaluation is the most critical activity in any composite development programme and its importance in aerospace activities is all the more critical. The role of NDE is not limited to just defect detection alone, but also extends towards refining/re-defining manufacturing processes and adding value to product development. NDE has a key role in ensuring quality and structural integrity thereby guaranteeing reliability and airworthiness of aircraft structures/components. This facility consists ultrasonic C-scan facilities capable of scanning components with doubly curved and complex contours of size up to 9 m x3 m x1.2 m, high resolution video scope, rapid scan linear array system with wheel probe, Digital Radiography, X-Ray Machine etc. capable of carrying out the NDE inspection of composite structures.

Techniques applied in this facility:

-

Ultrasonics – A-Scan, C-Scan, Air-coupled, Array Rapid Scan

-

X-ray Fluoroscopy

-

Infrared Thermography

-

Acoustic Emission

-

Automated Woodpecker

-

Videoscope

Major clients of this facility

Min. of Defense, HAL, TAML & a host of other private firms.

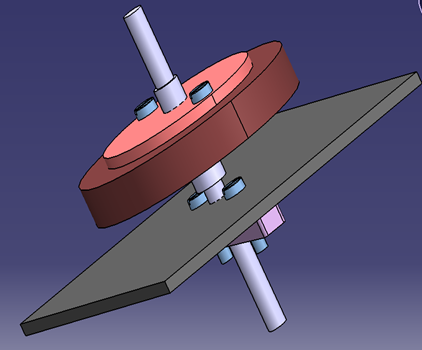

Air Coupled Ultrasonic system

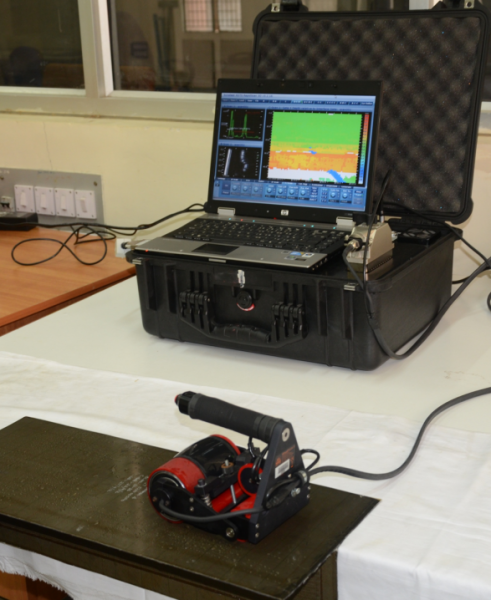

Rapid Scan Linear Array System Video scope

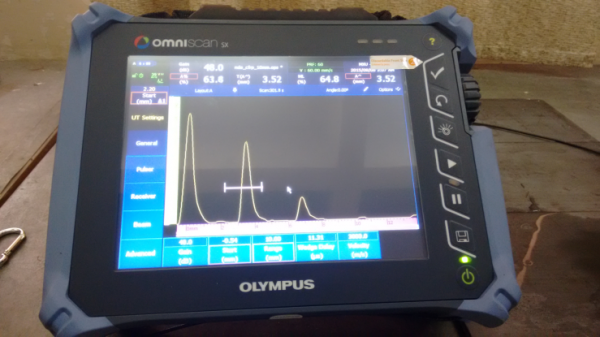

Ultrasound A scan Digital Radio Graph X ray Machine

Thermography Acoustic Emission

English

English हिन्दी

हिन्दी