Full scale Structural Testing facility

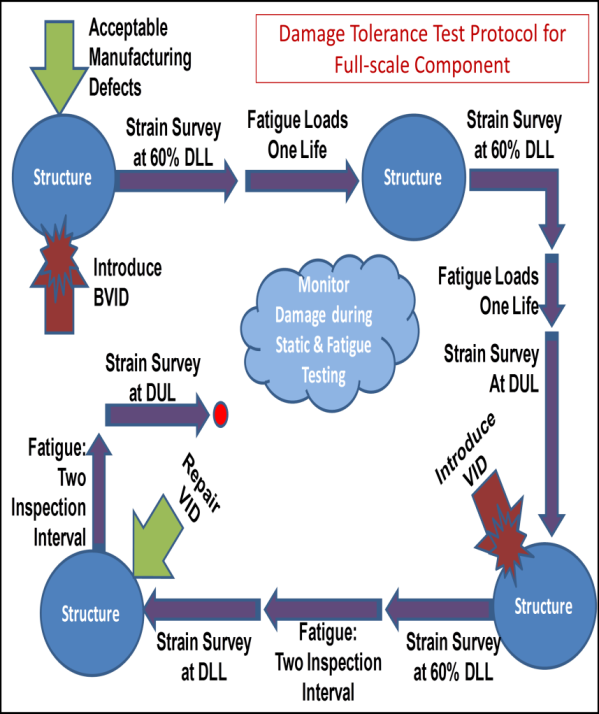

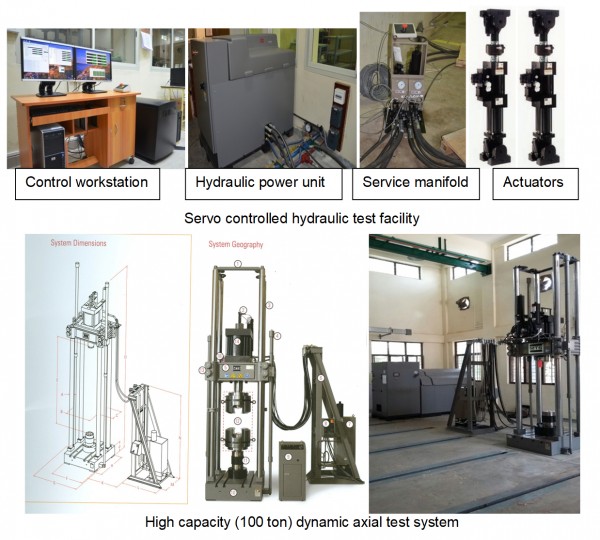

Full scale structural tests are essential to qualify the structure for flight. ACD- NAL has state-of-the-art test facility to conduct static and fatigue testing for full-scale aircraft composite structures and major components. The facility is managed by technical personnel having experience in structural testing of variety of aircraft structures in a cost-effective and timely manner.

The facility consists of equipment and systems capable of carrying out tests towards

- Performance of static & fatigue load tests on primary airframes, subsystems and components

- Investigations into damage tolerance characteristics, crack propagation and residual strength

- Determination of deformations, stiffness, fracture strength and fracture characteristics

- Development of test concepts, test fixtures, load frames and post-test documentation

Specifications

This facility consists of

- MTS hydraulic power supply unit of up to 100 lpm at 3000 psi

- 10 channel Servo Control system and extendable up to 32 channels (capacity of 53 ton servo controlled hydraulic jacks)

- Capacity of 50 ton manual control hydraulic loading cylinders

- 24 channels Universal Data acquisition system for static and fatigue measurement of strain, displacement, pressure and temperature

- 10 non contact,18 draw–wire sensors for displacement measurements

- High capacity (100 ton) dynamic axial test system

Major clients of this facility:

Government, public sector, PSU private sectors, R&D establishments, DRDO and Educational Institutes

English

English हिन्दी

हिन्दी