Bearings & Rotor Dynamics Laboratory

Bearings & Rotor Dynamics Laboratory of Propulsion Division comprises of National Test Facility for Rolling Element Bearings and Advanced Bearings and rotor dynamics facility.

1) National Test Facility for Rolling Element Bearings

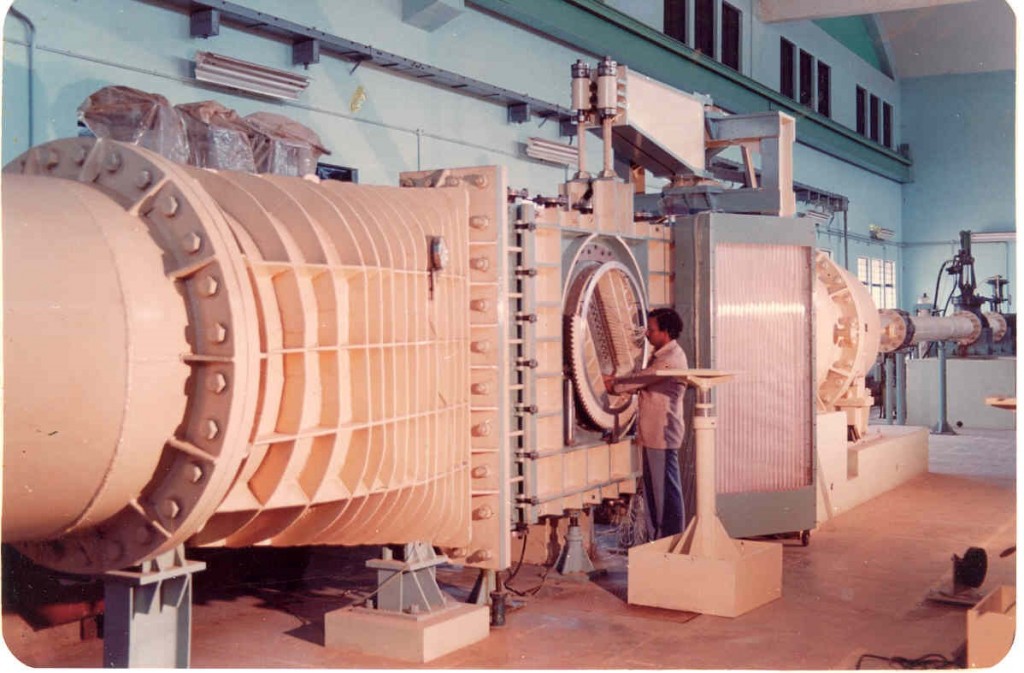

National Test Facility for Rolling Element Bearings in Propulsion Division is a major National facility for the performance evaluation of aerospace quality rolling element bearings and lubricants. This facility has been established in accordance with the Joint Service Specifications (JSS) prepared by the Centre for Military Airworthiness and Certification (CEMILAC), Bangalore. Facility is acting as a nodal agency for testing, indigenously developed aerospace quality rolling element bearings using proven lubricant or indigenously developed lubricant using proven aerospace quality rolling element bearings, under real time conditions. Actual level of loads, speeds and temperatures as experienced by bearings in aircraft gas turbines can be simulated in this facility. Apart from the above, this facility is also catering to the testing required for certification of rolling element bearings procured from secondary sources for aerospace applications.

The facility comprises of a bearing fatigue test rig for testing bearings upto 300 mm outer diameter and speeds upto 25,000 rpm under various loads and lubrication conditions. Fatigue test rig has a provision to rotate both the races of bearings independently in clockwise and anticlockwise direction up to 16500 rpm. It has a 10,000 Class clean room housing all the necessary metrology equipment. Other test set-ups that have been established in the facility include rigs for estimating static load capacities of rolling element bearing assemblies and bearing components, frictional coefficients in the bearings, sphericity of the balls, wobble in the bearings and dimensional stabilities. Equipment for evaluation of shear stability, extreme pressure of oil and an atomic absorption spectrophotometer have also been commissioned.

- Specifications: Bearing Fatigue Test Rig

- Single Spool Rotation:

- Speed : Up-to 25000 rpm (Accuracy 0.1 %)

- Load : Up-to 200 KN (axial & radial) (Accuracy 0.1 %)

- Oil Flow : Up-to 40LPM

- Oil Inlet Temperature : 0-150 C (Accuracy 0.1%)

- Bearing Size : Up-to Ø300 mm of outer race

- Inter-shaft (Both Race Rotation) Bearing Test Rig

- Speed (Inner &Outer race): Up to 16,500 rpm

- Radial Load : Up-to 25kN

- Radial Unbalance load : Up-to 12.5kN

- Axial Load : Up-to2kN (Provision)

- Inlet oil flow rate : Up-to 40LPM

- Oil inlet temperature : Up-to 125 C

- Bearing Size : Up-to Ø140 mm of outer race

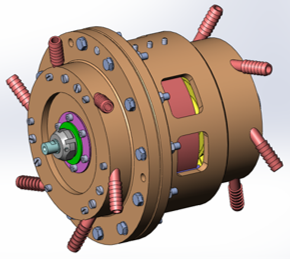

Bearing Fatigue Test Rig

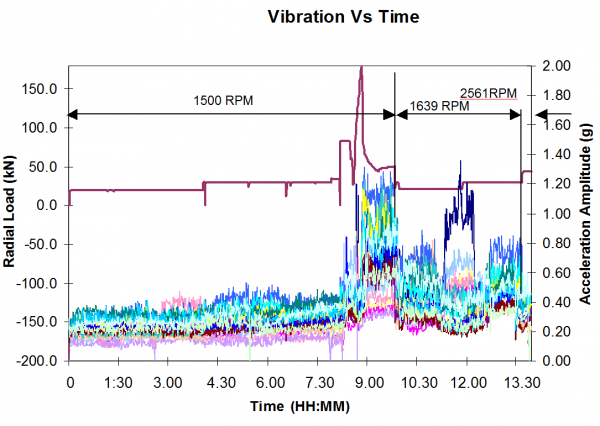

Typical Results: Bearing Endurance Testing

2) Advanced Bearings & Rotor Dynamics Facility (AB&RDL)

AB& RDL has capability to design, develop and evaluate the performance of lubricant free bearings, conventional & smart squeeze film dampers and high speed rotor systems. The facility comprises of dedicated tailor made test rigs for magnetic bearings, foil bearings, squeeze film dampers and high speed rotors. It is also equipped with high speed data acquisition systems for vibration, temperature, pressure, speeds, current and voltage data. It also has a dedicated team for condition monitoring and data analysis. Condition monitoring team has developed physics based model, various signal processing tools and artificial intelligence models (MATLAB based) related to aero engine gas path health monitoring. The models have been validated using engine test bed data.

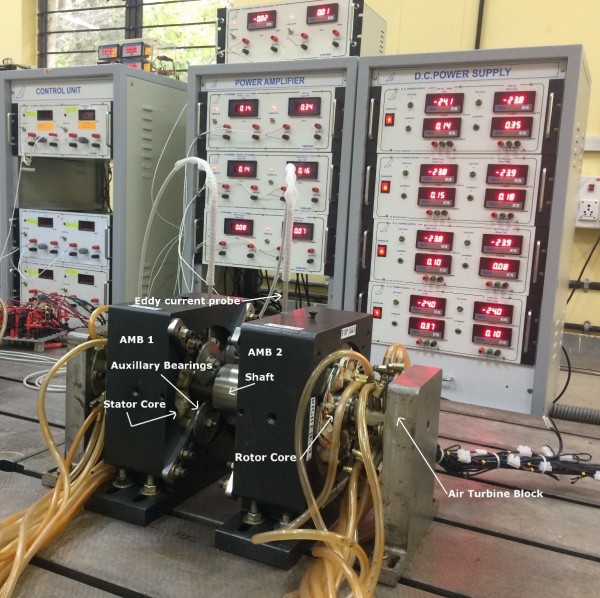

a) Magnetic Bearing:

Capability to design & develop active magnetic bearings to support both radial and thrust loads. Demonstrated 5 axis levitation of a 5 kg rotor up to 10000 rpm where the rotor was completely floating in air. The team also has successfully designed & installed active magnetic thrust and radial bearings for a 2 m long shaft weighing 100 kg and speed up to 2900 RPM in a vertical sodium pump prototype at IGCAR, Kalpakkam.

Active Magnetic Bearing Test Rig

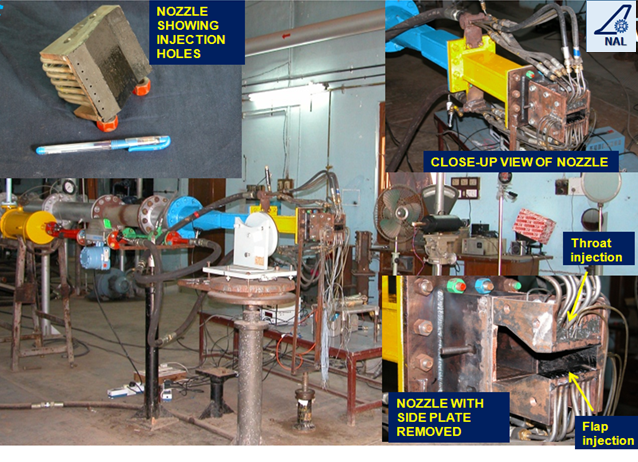

b) Foil Bearing

Successful design, development and demonstration of foil bearings for high speed and low load applications for the speeds more than 1 lakh rpm at rig level. Maximum weight of the rotor demonstrated is 3 kg up to the speed of 40,000 rpm. Team is currently working on foil bearings to improve the load carrying capacity and high temperature applications.

Continuous Bump Foil Bearings of Different Sizes

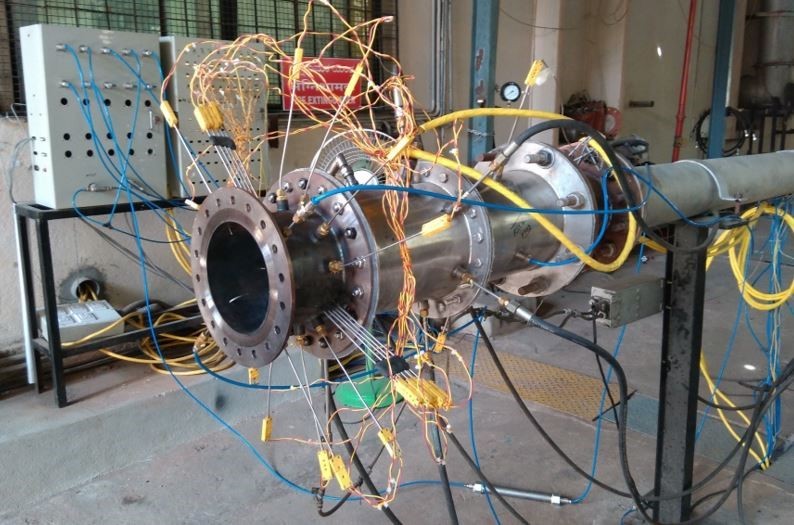

c) Squeeze film dampers

Capability to design, develop and evaluate squeeze film dampers of various configuration for specific application. The squeeze film damper for military gas turbine engine applications were successfully evaluated experimentally at very high level of unbalance and speeds (1920 gm-mm@ 14000 rpm & 468 gm-mm @ 18000 rpm).

- Techniques applied in this facility: Digital Signal Processing, Artificial Intelligence Algorithms, Physics based modeling

- Major clients of this facility : DMRL, IGCAR, GTRE, HAL, ADA, GTRE, CVRDE, ADE, BrahMos, GE, etc.

List of permanent Staff

Dr. Soumendu Jana - Senior Principal Scientist

Mr. Sadanand Kulkarni - Senior Scientist

Mr. L P Manikandan - Scientist

Mr Brijeshkumar Shah - Scientist

Mr Balaji S - Scientist

Mr Thennavarajan S - Technical Officer

Mr Vinodkumar Vyas - Technical Officer

Mrs Poornima N - Senior Technical Officer II

Mr Santhosh Kumar S - Scientist

English

English हिन्दी

हिन्दी