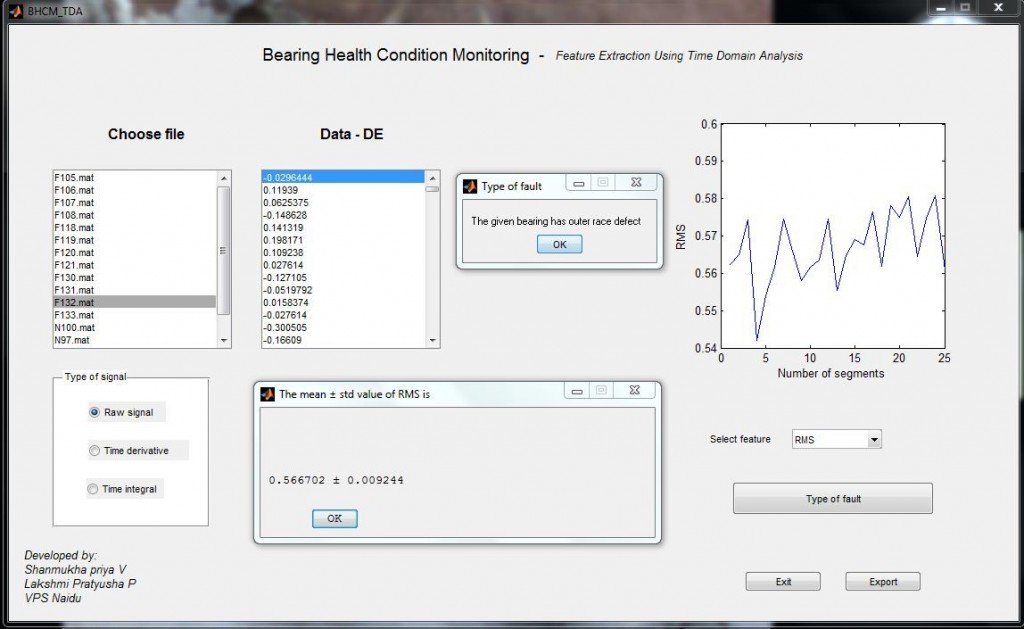

Electro-Mechanical actuator health monitoring

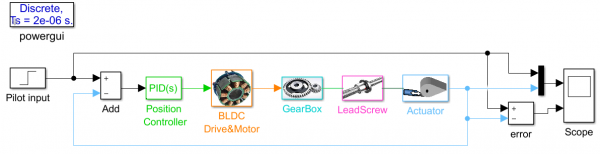

Off late, aircraft uses a combination of pneumatic, hydraulic, and electric systems. Future aircrafts will have electrical system and electrically powered equipment’s. This is called More Electric Aircraft (MEA), power-by-Wire, or All-Electric-Aircraft (AEA) where the power is transmitted through wires between the systems. This technology reduces the maintenance, increase the efficiency, and have more fault tolerant systems. One of the main systems in the MEA is electric actuation system that deflects the flight control surfaces such as rudder, aileron, spoiler etc... These actuators are either electro-hydrostatic actuator (EHA) or electro-mechanical actuator (EMA). EMA is a good candidate for electrical flight control actuation. EMA is used for a spoiler surface on B787. In general, EMA consist of Brushless Direct Current (BLDC) motor coupled to a ball or roller screw through a reduction gearbox. EMA prone to failure often because of having electrical and moving components hence condition monitoring is required. Current signature analysis techniques will be explored to monitor the condition of the EMA in flight.

Specifications

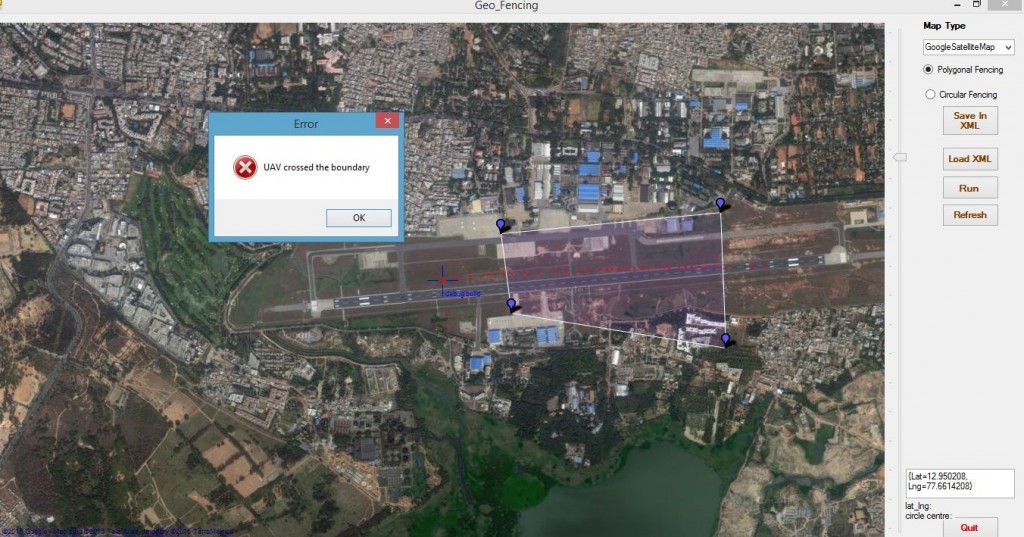

Facilities where this techniques is used

Maor mile stones / results of this technique

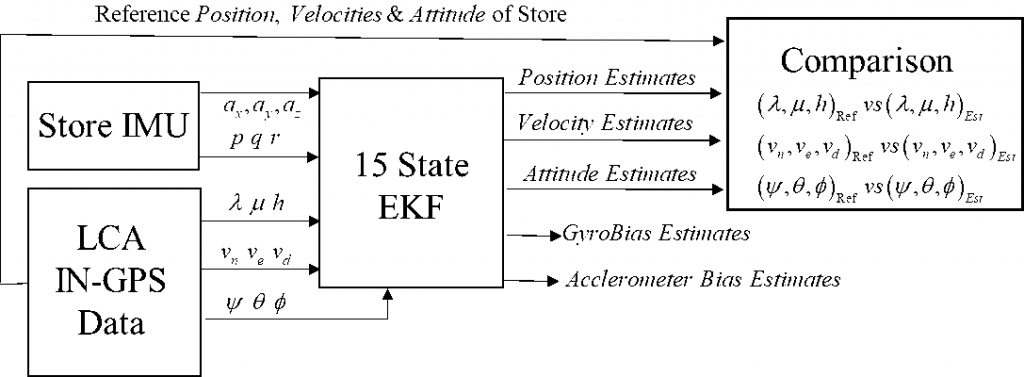

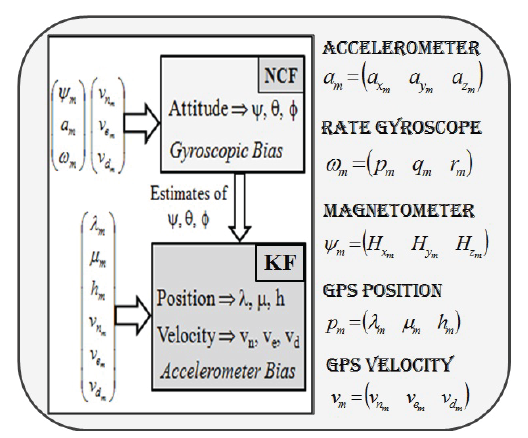

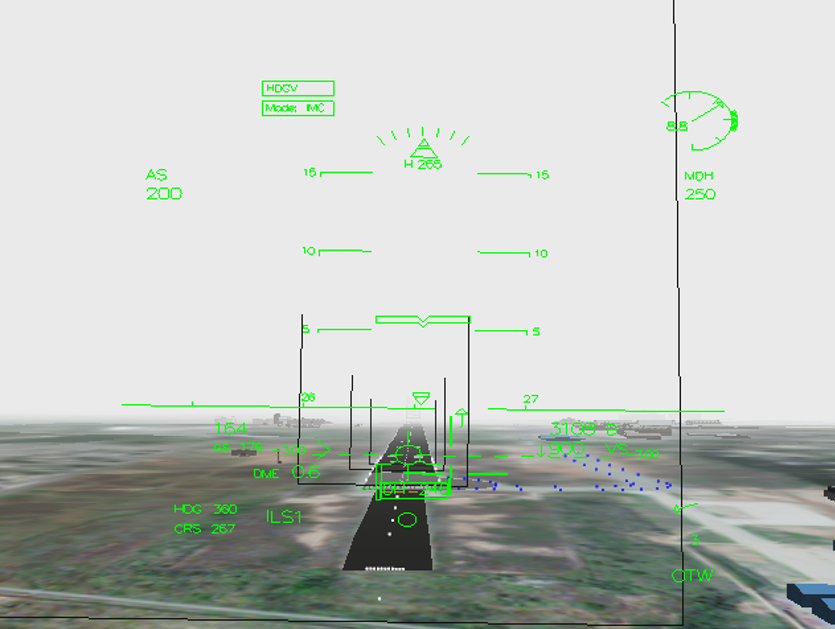

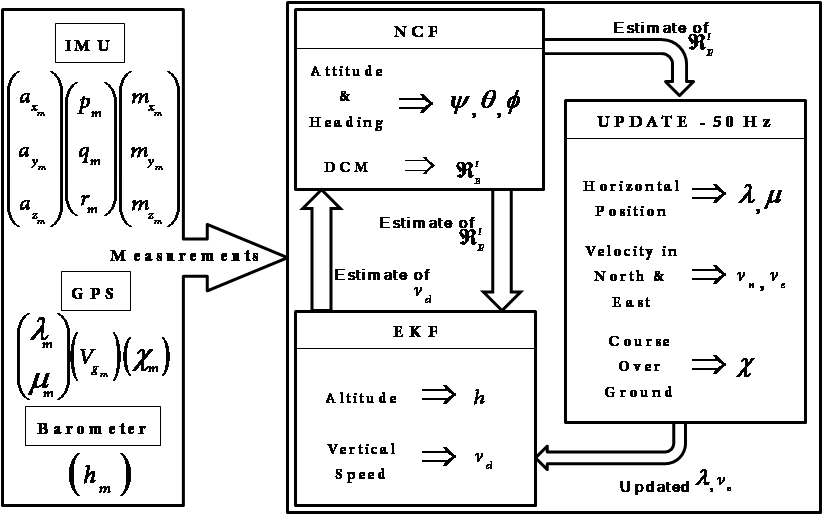

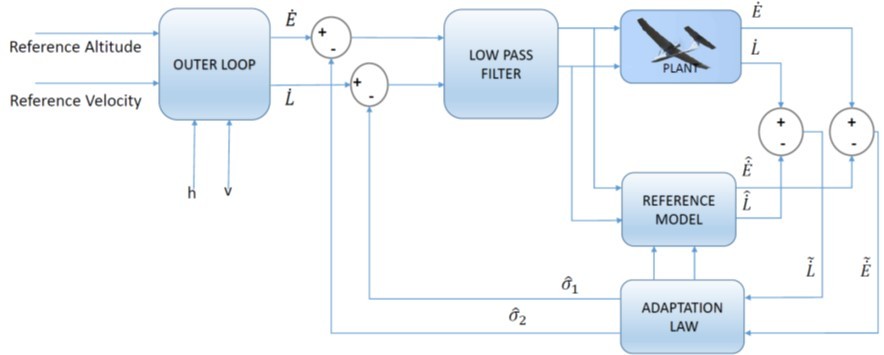

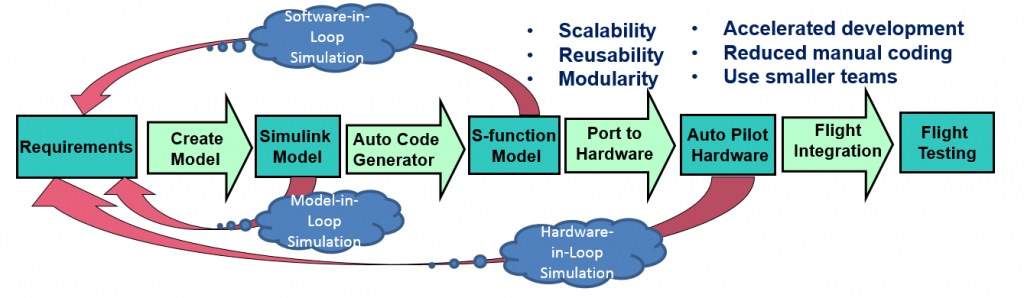

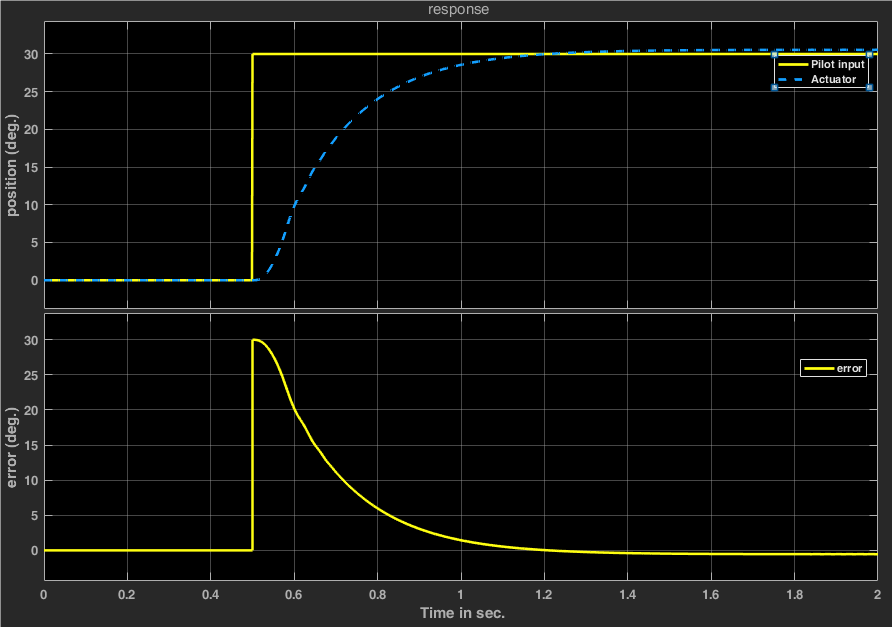

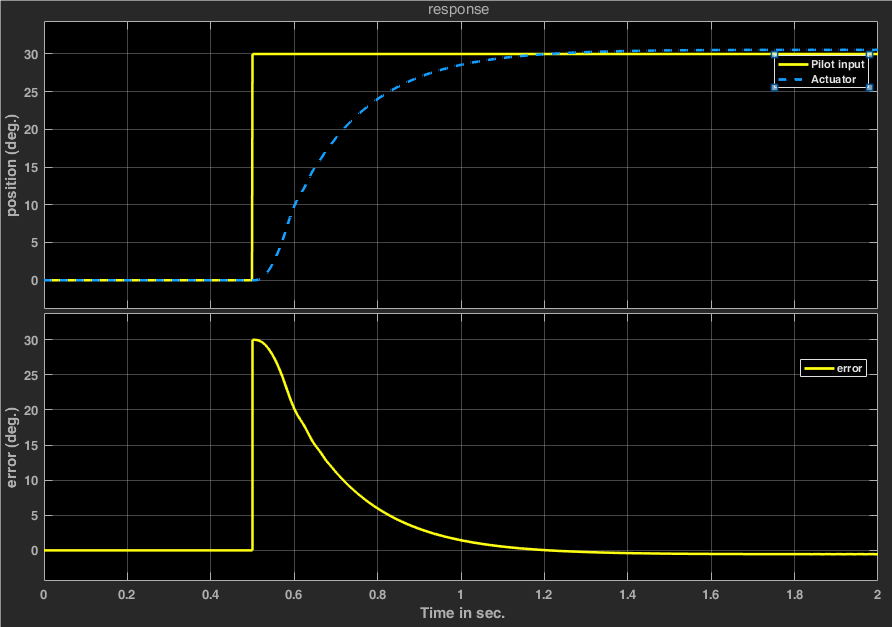

Fig: Information flow diagram of electro-mechanical actuator

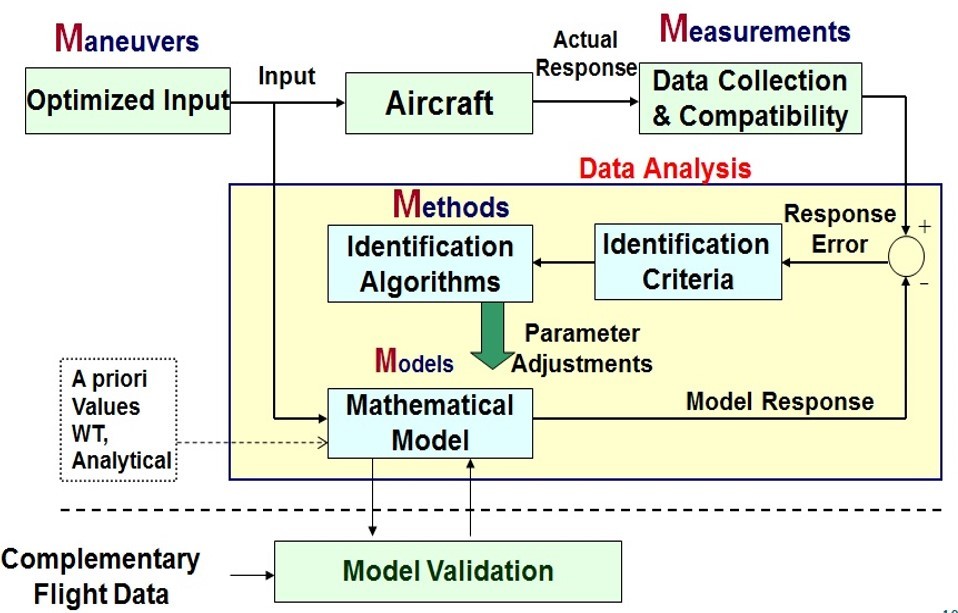

Fig: Input and actuator response

English

English हिन्दी

हिन्दी