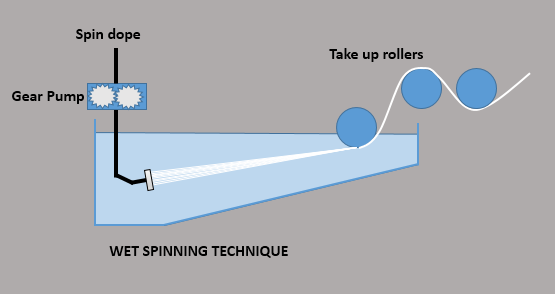

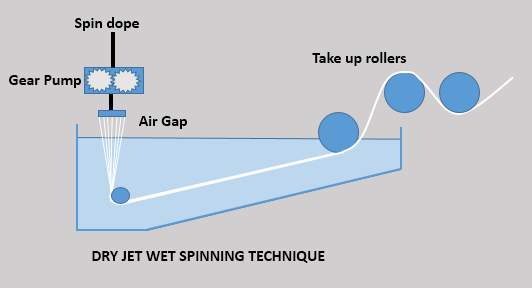

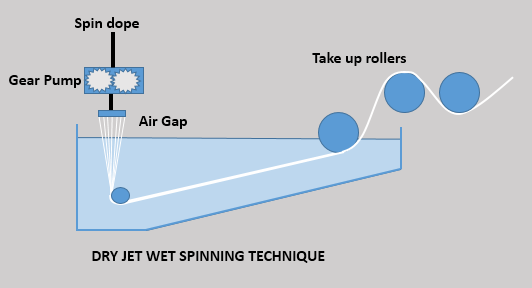

Dry jet wet fiber spinning technique

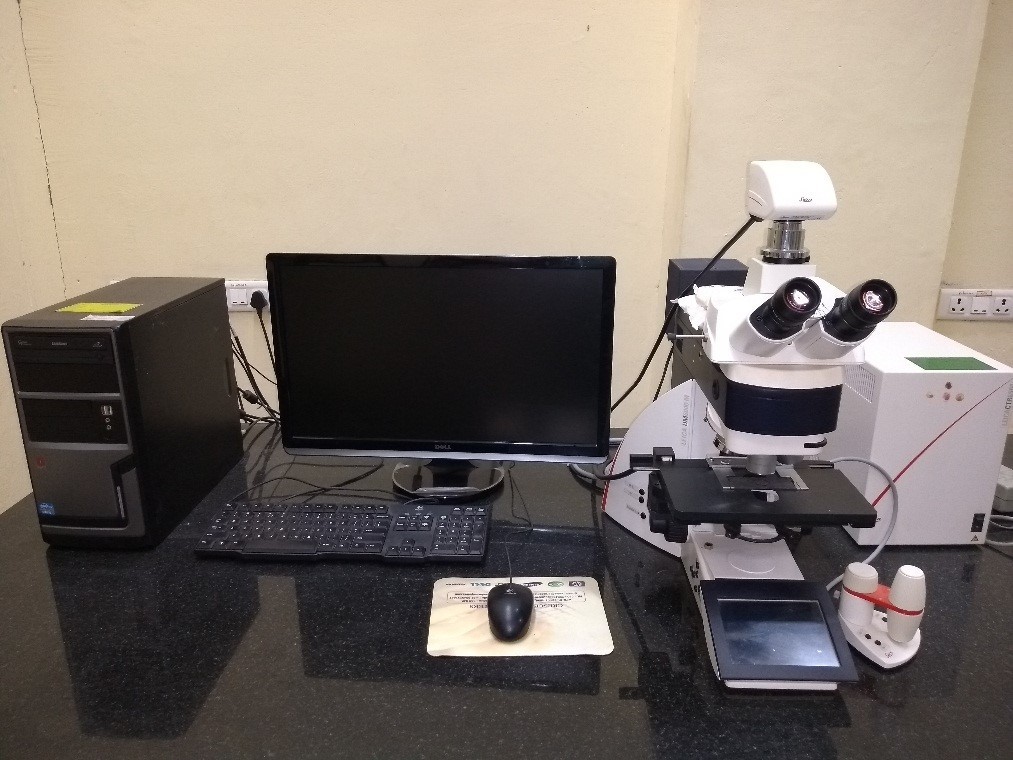

The dry jet wet spinning is a combination of both wet and dry spinning techniques for fiber formation. In this technique, the spinneret is located above the spin bath (<1 cm) with filament extruded vertically into the fluid. The advantages include the independent spin dope temperature and lesser stretching stress during fiber attenuation in comparison to wet spinning process. Applied stretching in air gap orients the filament before getting into the spin bath. The dry jet wet spinning facility is under development and integrable with the existing wet spinning line for post spinning operation.

Specifications

Dry jet spinning air gap: < 10 mm

Filament count: 1.5K, 3K

Facilities where this technique is used: Fiber spinning facility (F2)

Major mile stones / results of this technique:

English

English हिन्दी

हिन्दी