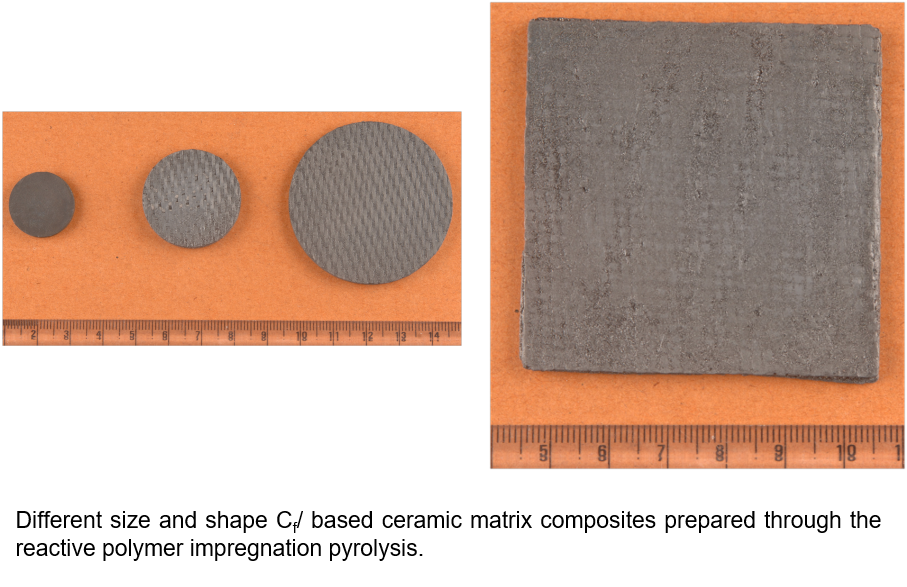

Reactive processing of monolithic and ceramic composites

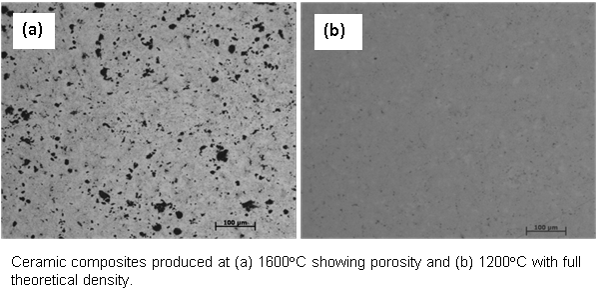

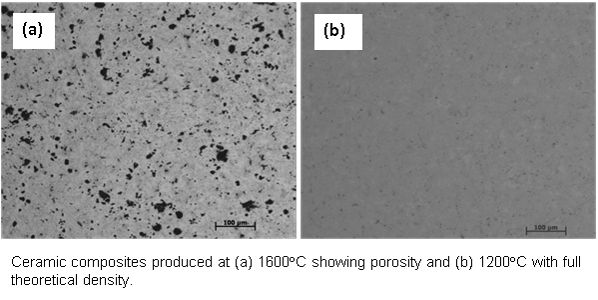

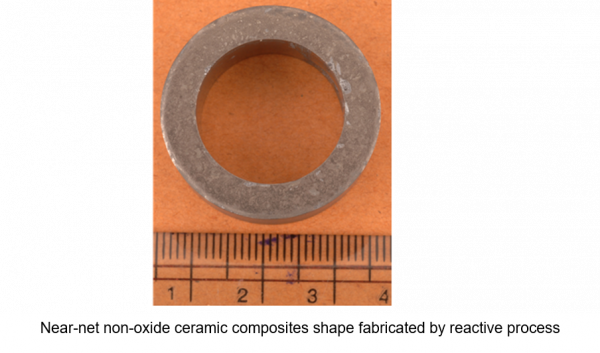

The reactive processing is a simultaneous synthesis and sintering method wherein high purity, high density with excellent mechanical properties ceramics and ceramic composites can be made at moderate temperature and pressure. In this process, the required powders such as elemental powders or elemental metal with compounds can be mixed in a high energy ball mill followed by vacuum/air drying. The required size can be fabricated by cold pressing using the hydraulic press. Samples assembled in a graphite die and reactive processed at different pressure and temperatures. It is established that the sintering temperature is 0.35 to 0.5 times of the individual non-oxide ceramics. Since the processing temperatures are lower compared to those reported in the literature and it is cost-effective processing method. This technique is also capable of producing the dense- near net- complicated shapes by economic compared to the available methods.

English

English हिन्दी

हिन्दी