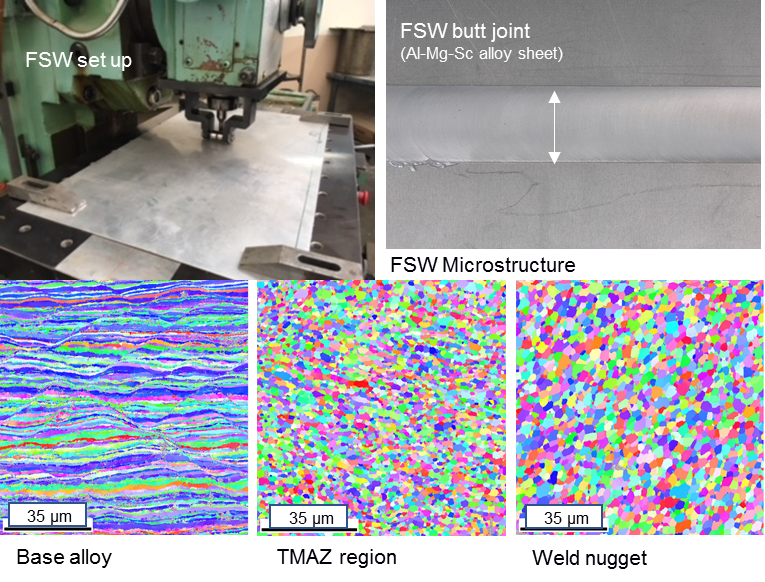

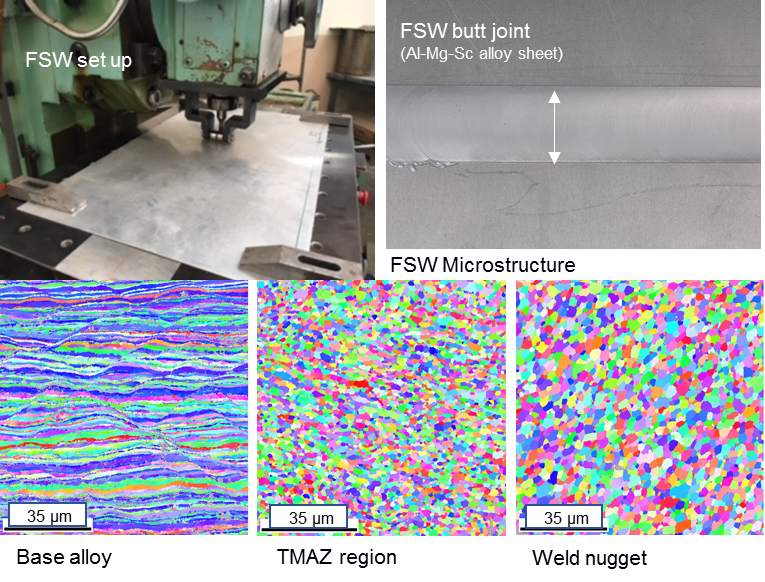

Friction Stir Welding (FSW)

The Materials Science Division (MSD) of CSIR - National Aerospace Laboratories has been carrying out work on Friction Stir Welding for the past three years. The Division has successfully developed the technique for high quality welding of Al-based alloy sheets of varying thickness.

Brief description of the technique

Friction Stir Welding (FSW), a solid-state joining process, is capable of producing high quality, high strength welds with low distortion in a wide range of materials including steel, titanium alloys, aluminum alloys etc. In recent years, FSW technique has been finding greater use especially in aerospace applications to take its unique advantage of cost benefits, weight reduction, time savings, part count reduction, lead-time flexibility etc.

In this technique, a rotating tool is plunged into the work piece until the shoulder comes into contact with the work piece surface. The frictional heat generated plasticizes the material and as the tool traverses along the joint, material moves around the tool producing the joint behind the tool. FSW process is considered as a green technology due to its energy efficiency (requires considerably less energy as compared to conventional welding methods) and environmental friendly (no melting occurs during welding, employs non- consumable pin, no flux, no gas, no filler materials).

English

English हिन्दी

हिन्दी