Mouldless casting of ceramics (MCC)

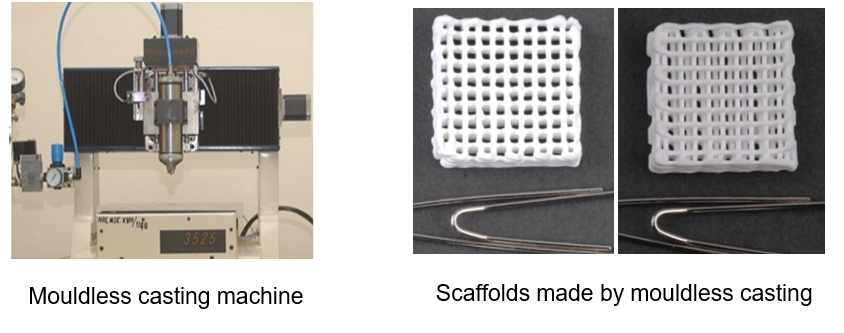

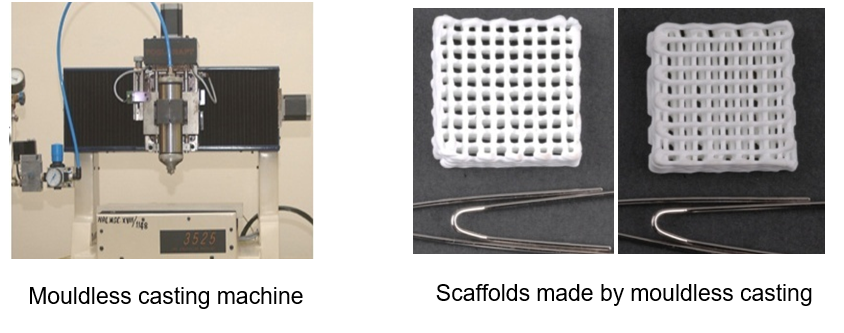

Materials Science Division, CSIR-NAL has developed a unique shaping method called Mouldless Casting for advanced ceramic materials to fabricate scaffold structures having continuous channeled pores in 3 directions. This is an additive manufacturing method which involves mouldless fabrication of shapes through computer aided designing and layer by layer deposition of ceramic slurry/paste by a computer controlled device.

Brief description of the technique

The mouldless casting method developed at NAL, involves colloidal processing of advanced ceramic powder in de-ionised water. The ceramic slurry having required consistency and rheology is achieved based on the surface chemistry of fine particles dispersed in a liquid medium. High solid loaded slurry having shear thinning behavior is extruded through a fine nozzle and deposited in X, Y direction and built in z direction into a scaffold structure having continuous channeled porosity. The team has worked extensively and optimized the method for few engineering ceramic materials like alumina, zirconia and bioceramic calcium phosphate. The product made are sintered to near theoretical density and the physical, microstructural and mechanical properties are evaluated in comparison with those obtained for samples prepared by other established techniques like slip casting and gel casting. As an outcome of this investigation the scaffolds fabricated from calcium phosphate ceramics were tested for its intended application in the biomedical field and proved biocompatible through in vitro and animal studies.

This technique involves synchronized knowledge of Chemistry, Materials Science, Ceramic science, Basics of manufacturing and designing.

English

English हिन्दी

हिन्दी