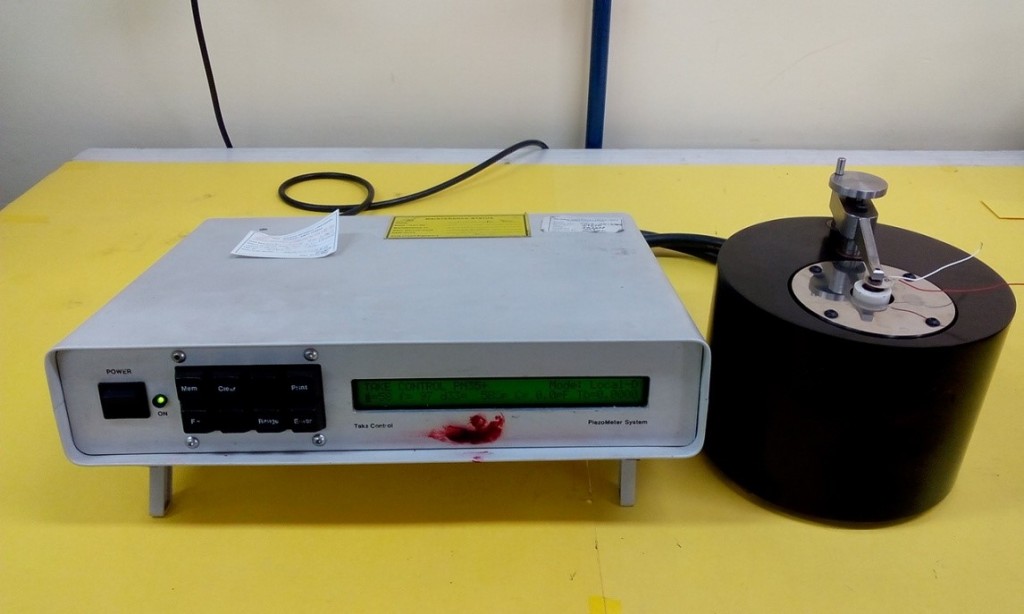

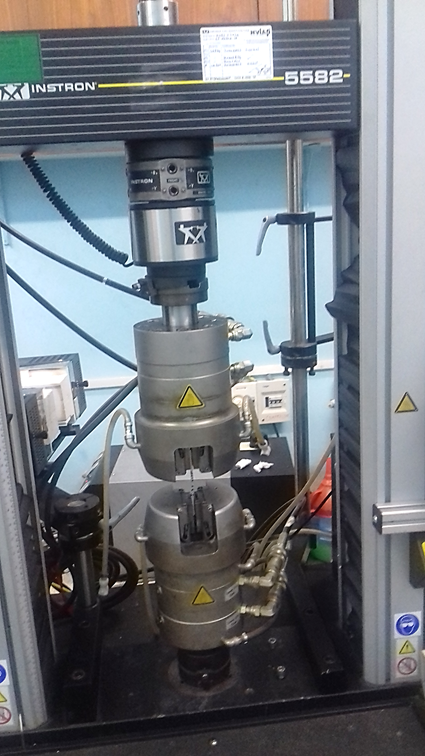

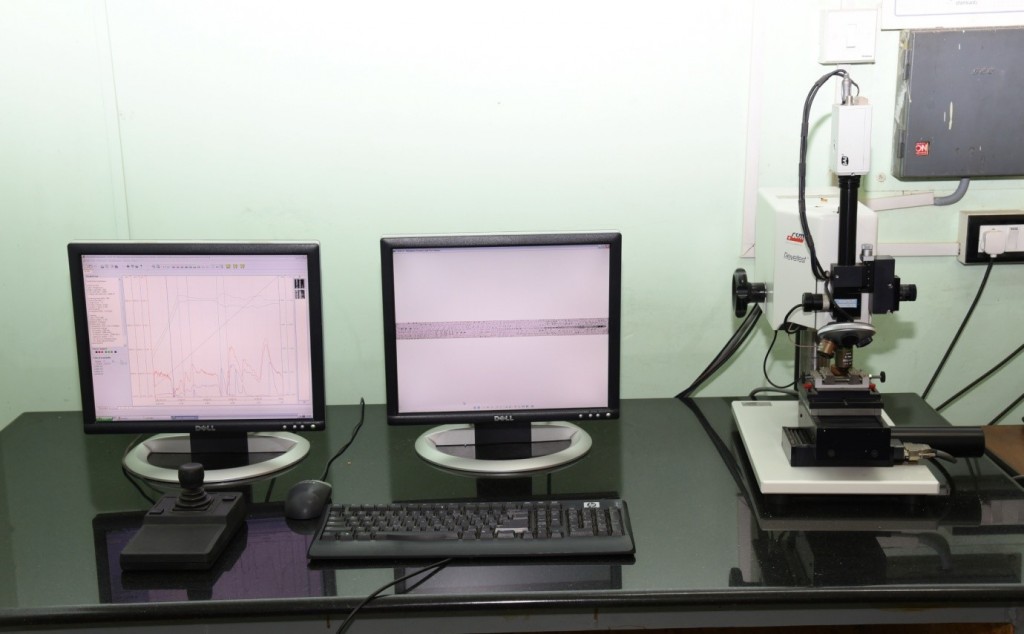

Tape Casting and Multi Layered Fabrication Equipments

Tape Casting and other equipments such as Scree Printer, Stacker and Dryer, Isostatic Laminator and Precision Cutter are used for fabrication of piezoelectric / PZT Multi-Layered (ML) stack actuators, Multi Layered Ceramic Capacitors (MLCC), preparation of thin ceramic tapes (Alumina, Zirconia etc.). An integrated facility of above equipments are available in our lab. The equipments already used successfully for fabrication of PZT multilayered stacks typically of 100-120 layersof thickness in the range of 20-200mm with Pt or Ag-Pd as internal electrode.

Tape Casting and other equipments such as Scree Printer, Stacker and Dryer, Isostatic Laminator and Precision Cutter are used for fabrication of piezoelectric / PZT Multi-Layered (ML) stack actuators, Multi Layered Ceramic Capacitors (MLCC), preparation of thin ceramic tapes (Alumina, Zirconia etc.). An integrated facility of above equipments are available in our lab. The equipments already used successfully for fabrication of PZT multilayered stacks typically of 100-120 layersof thickness in the range of 20-200mm with Pt or Ag-Pd as internal electrode.

|

Equipment Details |

Key Features |

Application Areas |

|

Tape Casting Machine: Casting width: up to 220 mm Tape speed: Adjustable, up to 3.5 m / min Tape thickness: 20-200 mm |

|

|

|

Printing and laminating machine Maximum Printing area: 160x160mm Printing Accuracy: ± 10 mm |

|

|

|

Iso pressing machine Pressure: 5-50 MPa Compressed air: 0.7 MPa; 600 l/min |

|

|

|

Precision Cutter Size of Bar (max): 160 x 160 x 5 mm. Compressed air: 6 bars, 60 l/min

|

|

English

English हिन्दी

हिन्दी