3D weaving

Near net preforming and 3D textiles designs and engineers the preform to meet the functional and performance requirements of the end product. Embracing the formative approach philosophy, the technology uses the concepts of lean manufacturing, creative textile designing and precision weaving. The third direction threads in 3D textiles, enables a fine balance of the in-plane properties with the out-of-plane properties, which is a typical requirement in aircraft structural applications such as wing root fittings, stiffener elements, landing gear etc., This balance of properties is achievable due to the myriad weave architecture possibilities coupled with the choice of thread types and loom settings. Other avenues for the technology lies in thermo structural applications such as the nozzle flap of a gas turbine engine, personnel and vehicle armours, crashworthy sections in automobile and medical textiles. These developments are carried out, as feasible, either on commercial weaving looms available in the textile industries (with NAL’s intellectual Participation) or on specialised 3D weaving machinery specifically built for this purpose at NAL.

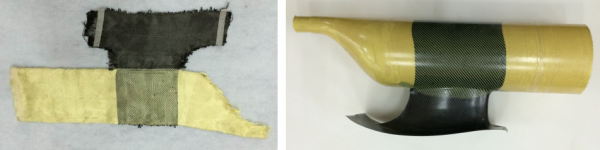

Photographs of preforms

T Stiffener insert developed using Near net Preforming approach

Near net preforming for the fuselage portion of a Micro Air Vehicle utilising the textile concepts of closed contour weaving and hybridisation approaches(left) and the ensuing composite (right)

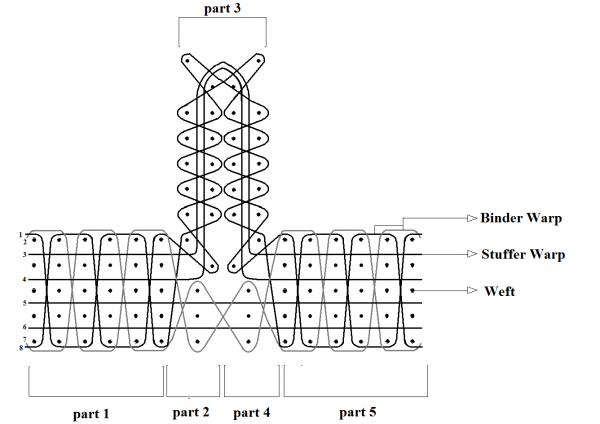

A creative 5 part weave design utilising the concepts of Near-net preforming and 3D weaving to develop the T stiffener preform

T stiffener carbon preforms developed using the above creative weave design

English

English हिन्दी

हिन्दी