Vacuum bag moulding

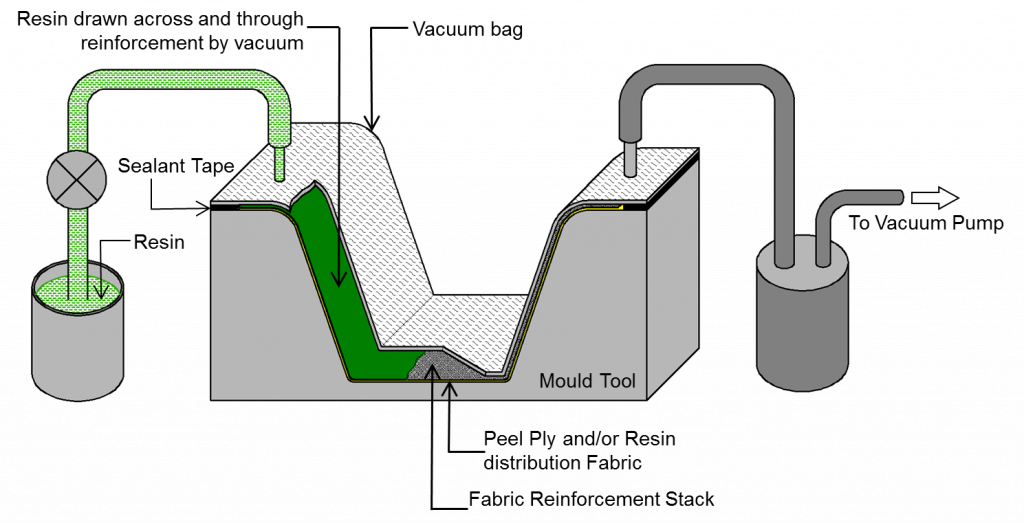

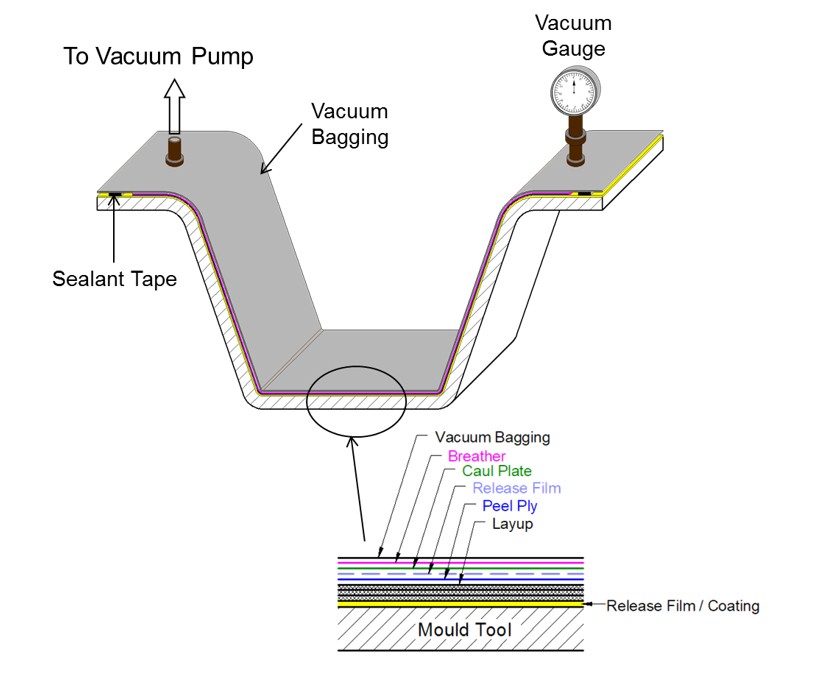

This method is an extension of the wet lay-up process in that the pressure is applied to the laminate once laid-up in order to improve its consolidation. This is done by sealing a flexible plastic film or an elastomeric membrane (silicon, nylon or polyimide) commonly called as “vacuum bag” over the wet laid-up laminate and onto the tool. The air under the bag is extracted by a vacuum pump and thus up to one atmosphere of pressure can be applied to the laminate to consolidate it, while ensuring removal of air pockets to maximum extent. Thus, the vacuum bag technique is an improvement over the contact moulding process in that; it provides a near void free composite with greater control over the thickness and fibre fraction of the moulded product. Further, in the vacuum bag moulding technique, several processing aids like a porous peel ply, a perforated plastic film (a porous plastic film) and a non-woven fabric breather are placed between the vacuum bag and the wet layup to facilitate removal of excess resin from inside out under the influence of a uniformly distributed vacuum. Figure 3 below shows a schematic of the above process.

English

English हिन्दी

हिन्दी