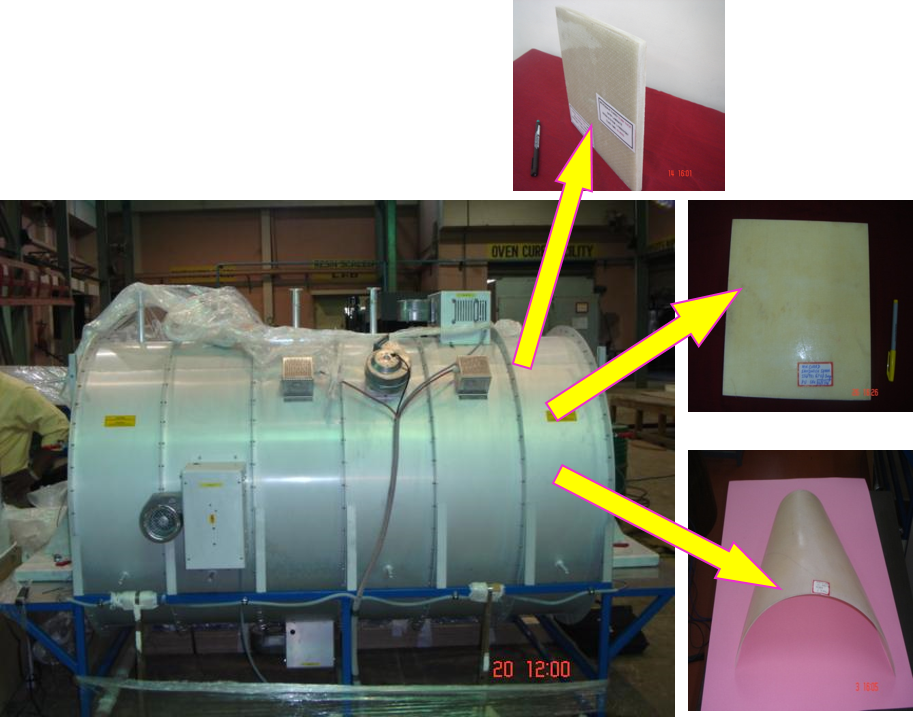

Computer Controlled Fabric Impregnation Machine

This Computer Controlled Fabric Impregnation Machine (CCFIM) is a versatile facility, first of its kind in the country, which can handle a wide variety of reinforcements and matrix systems. It is meant to replace the cumbersome manual resin impregnation processes, ridden with drawbacks likd non-uniform wetting of fabrics, weave distortions and poor quality of impregnation, due to their dependence on human skills. It further protects the workers from occupational hazards, also rendering the composite product development both eco-friendly and cost-effective.

The machine impregnated fabrics (Just-In-Time prepregs – JIPREGS) can be directly transferred to the moulds and converted to products, by the standard moulding technique (Room Temperature Vacuum Bag Moulding, Compression Moulding, etc.) thereby eliminating the use of sophisticated autoclave processes. The JIPREGS developed from this machine using various composite systems, can be conveniently used for development of prototypes and production versions of both aerospace and non-aerospace components.

Machine Capabilities – Salient Features

The CCFIM can be used for the impregnation of practically any class of reinforcements and compatible matrix systems for development of user-specific JIPREGS.

Reinforcements (BID, UD, Multiaxial):

Multiaxial Systems (both RT and Hot Cure):

- Glass Fabrics

- Carbon Fabrics

- Aramid Fabrics

- Bi-functional Epoxies & Vinyl Esters (Medium Tg)

- Multi-functional Epoxies (High Tg)

- Cyanate Esters (Very High Tg)

- Areal Density: 100 – 500 g/m2

- Fabric Widths : 300 – 1800mm

- Impregnation Rate: Upto 2 m / min

Milestones Achieved in Product Development

- 3.6m long CFRP blades for 4kW wind turbine system installed at NAL Wind Farm.

- 7.5m long CFRP blades for 10kW wind turbine system installed at Nagarbhavi, Bengaluru.

- 13m Dia. Weather Radomes of Doppler Weather Radar of BEL/ISRO for end user IMD. These radomes are installed at Bhuj-Gujarat, Cherrapunji-Meghalaya, Gopalpur-Odisha, Kochi-Kerala, Sriharikota-Andhra Pradesh.

Potential Applications

The JIPREGS made out of this machine can be used for rapid production of airframe components like fuselage, wing, control surfaces, empennage, etc., of the all composite aircraft (e.g. HANSA-3 and its variants) and components for SARAS aircraft, radome panels, etc. signifying its immediate applications.

The functionality of the machine can be further enhanced to develop STORABLE high temperature PREPREGS, with the matrix chemistry taken care of, for use in even more-advanced applications covering components for LCA, ALH, LTA, RTA, etc.

End Users

- National Aerospace Laboratories (NAL)

- Aeronautical Development Agency (ADA)

- Bharat Electronics Limited (BEL) & other Public Sector Undertakings (PSUs)

- Defence Research Development Organizations (DRDO – Labs)

- Indian Space Research Organization (ISRO)

- Private Sector Industries

English

English हिन्दी

हिन्दी