Compressed Air Facilities

Compressed air facility supplies compressed air to all the facilities in CSIR-NAL Belur campus

• Two numbers of 4-stage centrifugal compressors with latest control system

• Three numbers of 2-stage reciprocating compressors driven by diesel engine

• Two numbers of 6-stage centrifugal compressors

• Air receiver capacity: 3600 m3.

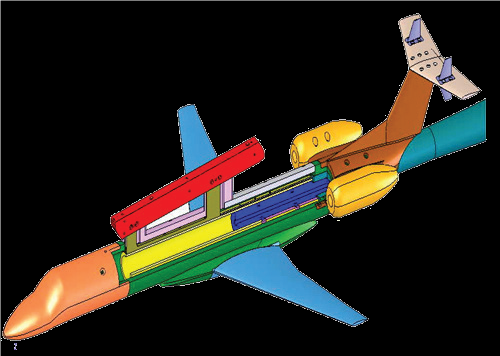

The Facility comprises 3-Individual compressor plants(TURBO, DECS and NCAF) along with its associated dryer systems, Dryer Reactivation systems, Cooling water system, Cooling Tower, Water Treatment Plants and network of Air ducting with Air Storage Receiver system. The specifications of systems given in the following table-1(A-H) and all the systems are shown in Figs.1-5.

|

|

|

|

Make: Associated Electrical Industries(AEI) , U.K. No. of compressor plants: 02 (CENTRIFUGAL) Motor Rating: 2800 HP, 11 KV (Each) No. of Stages per Compressor : 06 (L.P-, H.P-2 Stages) L.P.Cylinder (4 Stages) H.P.Cylinder (2-stage) R.P.M- 7400 R.P.M- 13285 Pressure Ratio: 6.3 Pressure Ratio: 2.2

Free Air Delivery (F.A.D) : 283 m3/min (Each) Air Delivery pressure:165 psig Storage charge up Time :2 Hours/compressor |

Make: JOY-COOPER (U.S.A) No. of compressor plants: 02 (CENTRIFUGAL) No. of Stages per Compressor: 04 Motor Rating: 2815 HP, 11 KV (Each) Free Air Delivery (F.A.D) : 283 m3/min (Each) Air Delivery pressure:165 psig Storage charge up Time :2 Hours/compressor

|

|

|

|

|

|

No. of Dryer systems:03 (Turbo,DECS,NCAF) No. of Dryer vessels:06 Type: Dual Adsorption type Desiccant Used: Silica Gel Beads( Mobil-SORBEAD’R’ ) Capacity of Volume flow: 20000 SCFM Desiccant load: 7500 Kg / Dryer vessel Drying cycle:4 Hrs Reactivation cycle: 8 Hrs Outlet air Humidity:0.0001 lb/lb Dewpoint: -38 deg C Heater Rating :340 KW Reactivation Temperature: 204 deg C |

Make: Shriram Tower Tech Ltd. Type: Induced Draught counter flow type Structure:RCC No. of cells: 03 No. of Fan blades/Cell :03 Type of Fan Blade: Adjustable pitch, FRP Amount of water to be cooled : 1215 m3/ Hr. Cooling Range: 8 - 9 deg C Hold up volume of Basin:150000 Ltr. Drift Loss: Less than 0.002% |

|

|

|

|

|

Make: Ion Exchange (India) Ltd. Process of Treatment: Ion Exchange Design Capacity: 360 Ltrs/min Output Between Regenerations (O.B.R): 200000 ltrs. Water Quality maintained: pH :7.0-7.5 Total Hardness: Less than 5 ppm Alkalinity : Less than 90 ppm

|

Make: Dexter Watertech Process of Treatment: Ion Exchange Design Capacity: 360 Ltrs/min Output Between Regenerations (O.B.R): 200000 ltrs. Water Quality maintained: pH :7.0-7.5 Total Hardness: Less than 5 ppm Alkalinity : Less than 90 ppm |

|

|

|

|

|

|

Total Storage Volume: 4500 m3 No. of Receiver Vessels: 07 (05 cylindrical + 02 Spherical) |

|

|

English

English हिन्दी

हिन्दी