Nickel-Titanium Shape Memory Alloys

The Materials Science Division (MSD) of CSIR - National Aerospace Laboratories has been carrying out R&D on NiTi Shape Memory alloys (SMAs) since 2002. The Division has successfully developed the know-how for the processing of NiTi SMAs in various semi-finished and finished product forms. The SMAs developed are suitable for both engineering and biomedical applications. The technology has been transferred to Mishra Dhatu Nigam (MIDHANI) Limited, Hyderabad, a Defence Public Sector Undertaking (DPSU), in the year 2017, for commercial production and marketing. Currently, collaborative research is underway with the leading medical institutes of the country for design and development of stents for biomedical applications.

The Materials Science Division (MSD) of CSIR - National Aerospace Laboratories has been carrying out R&D on NiTi Shape Memory alloys (SMAs) since 2002. The Division has successfully developed the know-how for the processing of NiTi SMAs in various semi-finished and finished product forms. The SMAs developed are suitable for both engineering and biomedical applications. The technology has been transferred to Mishra Dhatu Nigam (MIDHANI) Limited, Hyderabad, a Defence Public Sector Undertaking (DPSU), in the year 2017, for commercial production and marketing. Currently, collaborative research is underway with the leading medical institutes of the country for design and development of stents for biomedical applications.

Shape Memory Effect and Superelasticity

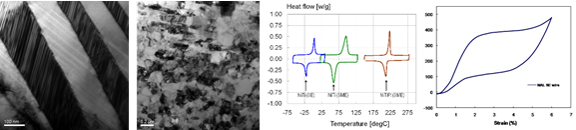

Nickel-titanium (NiTi) SMAs have received considerable scientific attention because of their two unique functional properties: shape memory effect (SME) and superelasticity (SE). SME is the ability of the material to be deformed at low temperature and then revert to its original shape upon heating above a critical temperature. SE is the ability of the material to experience large recoverable strains when deformed within a temperature range. These, combined with the superior mechanical properties and corrosion resistance make SMAs as promising class of material for a variety of engineering and biomedical applications.

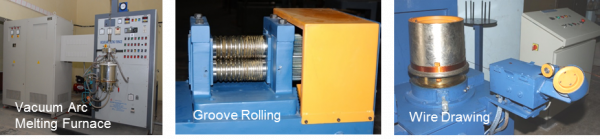

Processing Facilities

The laboratory is equipped with state-of-the-art processing facilities for undertaking R&D work on NiTi SMAs. The facilities include vacuum arc melting furnace, hot and cold rolling mills for wires and strips, wire drawing machine, heat treatment furnaces (controlled atmosphere and vacuum), special furnaces for shape memory heat treatment, set-up for stabilization of wire properties for repetitive strain applications.

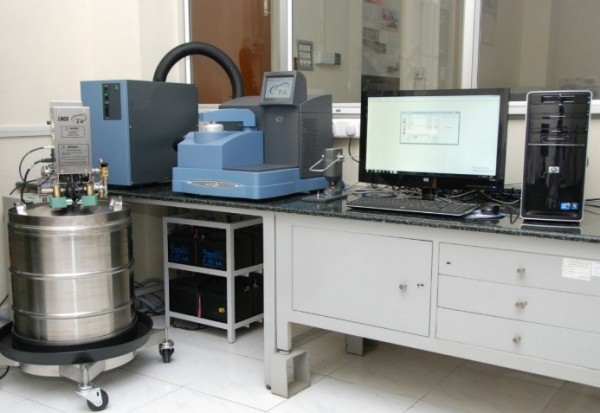

Characterization Facilities

The SMA laboratory has the characterization facilities for evaluation of functional and mechanical properties of NiTi SMAs under application environment. The facilities include differential scanning calorimeter (DSC), universal tensile testing machine (UTM), rotating beam fatigue testing machine for wires, thermo-mechanical fatigue testing machine,

Modulated Differential Scanning Calorimetry

Study of phase transformation

Make: TA Instruments

Model: Q2000

Key Features

Temperature Range: -180 to 500°C

Temperature accuracy: ± 0.1°C

Sensitivity: 0.2 µW

Baseline reproducibility: ±10 µW

Universal Tensile Testing Machine

Evaluation of tensile properties

Electro-mechanical system for tensile testing of thin specimens (wires/strips)

Make: Instron

Model: 3365

Max. Load: 5 kN

Temperature Range: -100 to 250°C

Key Features

Control: Fully automated through software

Speed Range: 0.01 to 1000 mm/min

Load accuracy: 0.5% of indicated load

Thermomechanical Fatigue Testing Machine

Evaluation of functional fatigue properties

Custom built apparatus for evaluation of thermo-mechanical fatigue behaviour of NiTi shape memory alloy wires. Conceptualized and designed by CSIR-NAL.

Make: Pragathi Solutions, Bangalore

Key Features

- Programmable heating /cooling cycle

- Joule heating & forced/natural cooling

- Strain measurement using non-contact laser

- Stress measurement using load cell

- Continuous data logging of stress/strain

- Closed loop strain control using servo motor

Rotating Beam Fatigue Testing Machine

Rotating beam fatigue machine can be used for testing of small diameter wire in a simple and rapid method for obtaining fatigue strength and endurance limit values to serve as quality indexes.

Make: Valley Instruments, USA

Model: 100

Key Features

Suitable for mechanical fatigue testing of thin wires with diameter as low as 100 µm

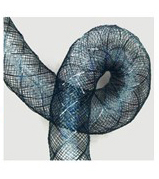

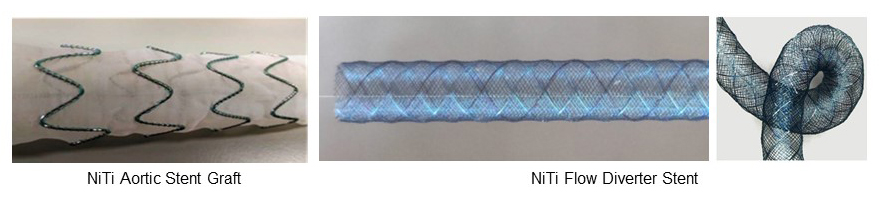

NiTi SMA Products

The laboratory has also developed expertise for shape setting as well as surface preparation of the products depending on the nature of the applications.

Engineering Products (technology transferred to MIDHANI, Hyderabad)

- Wires

- Rods

- Plates

- Strips

- Springs

Biomedical Products

CSIR-NAL and Sree Chitra Tirunal Institute for Medical Sciences and Technology, Trivandrum have jointly developed three NiTi wire based enodovascular products viz., Aortic Stent Graft (ASG), Flow Diverter Stent (FDS) device and Atrial Septal Defect (ASD) closure device. The Transfer of Technology for manufacture of FDS device and ASD closure device is in progress to M/s Biorad Medisys Private Limited, Pune

- R&D of NiTi base shape memory alloys for engineering and biomedical applications

- Processing of NiTi SMA wires and strips with SME and SE

- Microstructure, thermos-physical and mechanical properties evaluation

- Study of functional fatigue behaviour in application environment

- Design and development of customized shapes of NiTi SMA

- High temperature shape memory alloys (NiTiPt/Pd)

English

English हिन्दी

हिन्दी