Design and Development of cocured composite structures using VERITy/VARTM technology

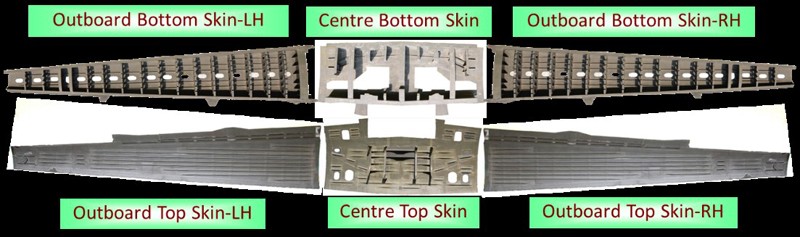

CSIR-NAL has pioneered the design & development of composite structures for national aircraft programs using innovative and cost-effective fabrication technologies. Advanced Composites Division on NAL has developed a low cost and proprietary Vacuum Enhanced Resin Infusion Technology (VERITy) for manufacturing of high quality composites. The scaling up of process from small laminate to full-scale wing structure is completed through a sustained and well-directed R&D and the full know-how is available with ACD. Several complementing technologies have also been developed like integrated tooling, automated resin infusion system and flow sensing techniques. Technology is successfully demonstrated in the manufacturing of cocured wing box for SARAS Aircraft.

The salient features of VERITy are:

- No special storage (-18°C). Raw material can be stored at room temperature

- Unlimited self-life, Manufacturing of large and complex parts integration leading to reduction in assembly cost

- Properties comparable to autoclave molding process

- Process cost benefits by 15% compare to prepreg/autoclave process

The technology can be used for manufacturing of large cocured structures due to infinite self-life.

The complete technology package for manufacturing a cocured structure consists of process design, infusion schemes depending on the part design, detail manufacturing drawings, composite tooling, detail manufacturing process sheets, quality records and the like.

English

English हिन्दी

हिन्दी