Functional Materials

1. PIEZO CERAMICS

R&D on piezo ceramics was initiated in MSD since beginning of this century, thanks to the support from CSIR five year plan and national program on smart materials (npsm). The program was started on synthesis of PZT and PMN powders, fabrication of multi-layered stacks. Thereafter, R&D work on lead free piezo materials such as BNT, BZT, BZT-BCT etc. synthesized. In recent times, energy harvesting using piezo materials and synthesis of high temperature piezo-resistive materials are carried out.

Development of piezoelectric and dielectric materials

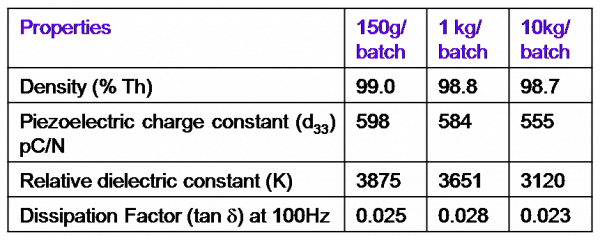

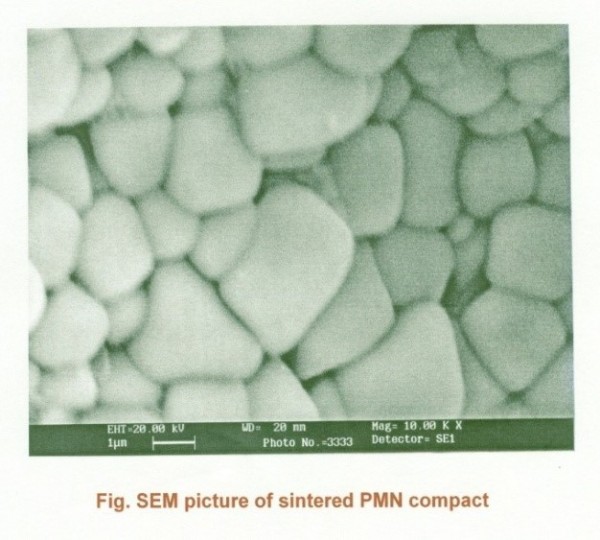

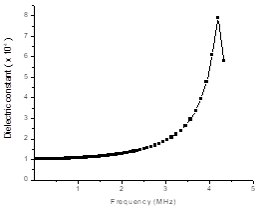

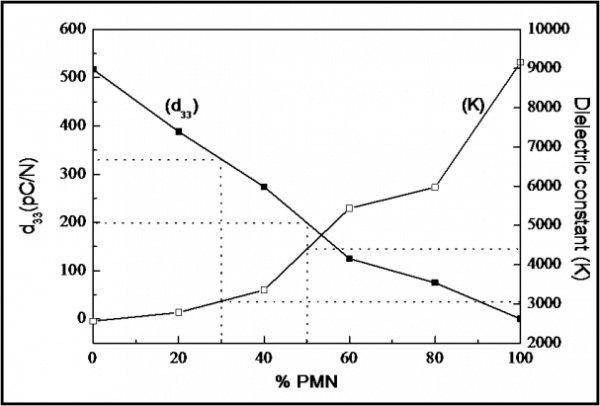

Soft grade PZT powders (PZT-5H) with high piezoelectric charge constant (d33 > 550 pC/N) was prepared with reproducible properties from batch to batch. Similarly, pyrochlore free Lead Magnesium Niobate (PMN) powder with high dielectric constant (K=10,335 at 100 Hz, RT) and (K=79,100 at 4.18 MHz) was prepared. These powders were prepared in lab scale (150gm) and then upscaled to 10Kg/batch with consistent properties. PZT powder doped with various dopants such as La, Nd, Nb, Ce etc. were also prepared and characterized for piezoelectric, dielectric and ferroelectric properties. PZT-PMN composite materials were prepared. As a result of this study, it is possible to design materials of different PZT–PMN compositions to generate required combination of piezo and dielectric properties for various applications. PMN–PT materials doped with Ceria is also prepared and characterized its properties. These materials have very good piezoelectric and dielectric properties and can be used for various applications such as multilayer capacitor and electromechanical systems.

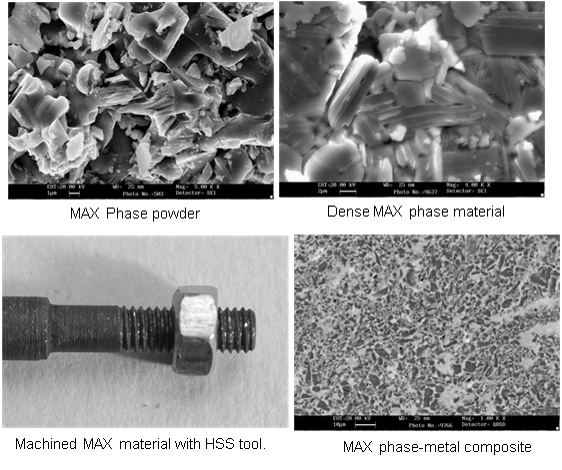

Properties of PZT powders

SEM of pyrochlore free PMN sintered pellet Dielectric constant Vs. frequency (at RT) of PMN.

Properties of PZT-PMN Ceramics

Lead Free piezo materials

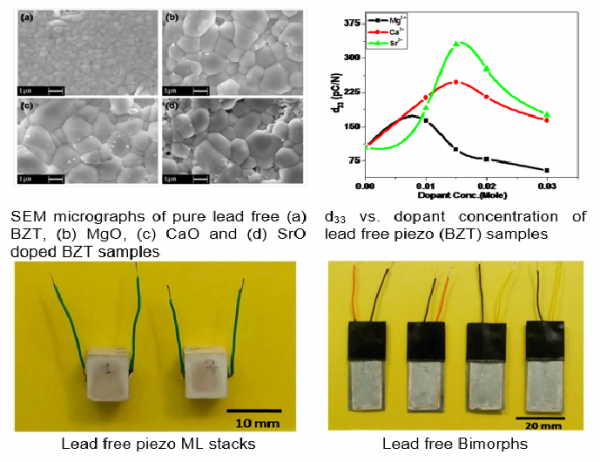

Piezoelectric ceramic materials without having PbO in its composition are called lead free piezo ceramics. These includes barium titanate (BT), barium zirconate titanate 9BZT), Sodium niobate, potassium niobate, potassium sodium niobate (KNN) etc. In recent years, lead free piezo materials are encouraged due to toxicity PbO. Low density of lead free piezo materials (<2/3 of PZT) is an important positive factor for fabrication of hydrophones. In our lab, lead free piezo materials in the system Barium Zirconate Titanate (BZT) doped with alkaline earth metal oxides such as MgO, CaO and SrO prepared and characterized. SrO doped BZT produced high piezoelectric charge constant, (d33 = 330 pC/N). Lead free piezo bimorphs and ML stacks fabricated and characterized.

Development of high temperature piezoresistive materials

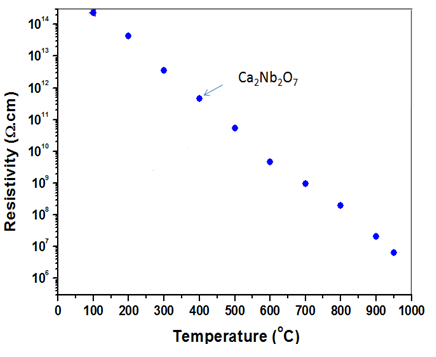

Synthesis of high Curie temperature (Tc) piezoresistive material for high temperature sensor application has been carried out. The materials were characterized for XRD, SEM, piezo resistivity up to 1000˚C and dielectric constant with respect to temperature. These materials are promising as high temperature sensor in gas turbine engines.

DC resistivity Vs. temperature of in-house prepared piezoresistive material

Piezoelectric Energy Harvesting using PZT devices

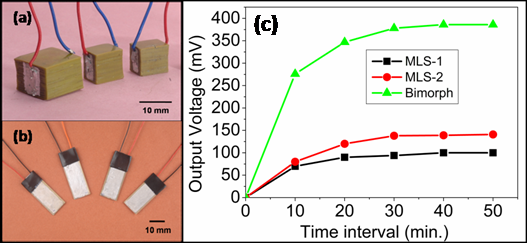

Vibration energy harvesting using in house developed PZT bimorphs and multilayered (ML) stacks were carried out. ML stacks of ~150 layers, each layer of 100 µm thick were fabricated using Pt- electrode as internal electrode and co-fired at 1250˚C/1h. Similarly, PZT bimorphs of thickness 280µm and area of 40 x 15 mm2 were fabricated. Energy harvesting study was carried out using a suitable assembled test set up and the output voltage produced by the devices were measured. The output voltage (450 mV) produced by bimorph was found more compared to PZT ML stacks (125 mV). Energy harvesting study of PZT unimorphs was carried out which generates maximum output voltage of 5.0 V. The energy generated able to glow LEDs.

(a) Photographs of fabricated PZT ML stacks, (b) PZT bimorphs and (c) Output voltage generated from PZT bimorph and ML stacks.

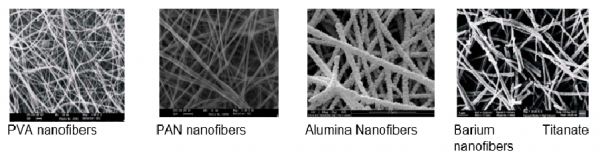

Development of polymer and ceramic nanofibers by electrospinning

Electrospinning is a simple versatile straight forward technique for preparation of nanofibers. In our lab at CSIR-NAL, various polymer and ceramic nanofibers such as PVA, PAN, Al2O3, BaTiO3, Mn3O4, SnO2, Samaria, lead free piezo BCTS nanofibers etc were prepared and characterized. These nanofiber membranes have applications in the area of water filtration for removal of fine particles and microbial elements, air /Industrial air filtration, light weight fabrics for defence and healthcare Industries.

2. PIEZO POLYMER

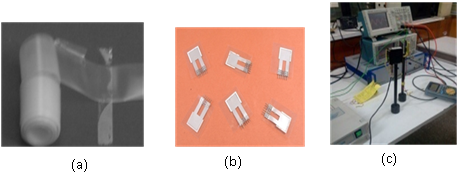

From a decade and a half, the piezo polymer group has gained expertise in the development of piezoelectric beta phase Polyvinylidene Fluoride (PVDF) films. The PVDF is a polymer known for its piezoelectricity having many advantages suitable for industrial and aerospace applications. Different techniques are adopted to develop PVDF films (as shown in fig 1a), which include solvent cast, hot press and the extrusion method. The films produced are in alpha phase. To achieve piezoelectric beta phase, a stretching unit has been designed and fabricated at NAL to stretch the film thermo mechanically, for which patent has been awarded. The films were characterised for mechanical, surface, structural, morphological, tensile and piezo properties. The beta phase films were then designed to make sensors and actuators (as shown in fig 1b). The sensors are checked for static and dynamic response. These sensors are useful for various applications like pressure sensor, vibration sensor, structural health monitoring, energy harvesting sector and as an actuator for flapping wing mechanism (as shown in fig 1c).

Over the past few years, the group has also acquired knowledge in preparation and characterisation of tailored PVDF composite films for various applications. This includes PVDF with PZT, ZnO, TrFe, onium salt and PANI nano fillers. The films were checked for suitability in storage capacitors, acoustic sensor and SHM.

a) Extruded PVDF film b)PVDF sensors c) PVDF as actuator

A brief of few applications is presented below:

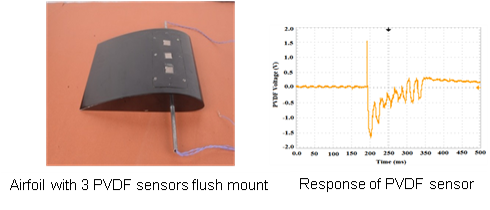

Surface Pressure mapping of MAV wings using PVDF sensors where PVDF sensors are used to measure pressure as a function of wind velocity ranging from 5-30 m/sec with a 10-degree angle of attack. The sensors are flush mounted on the air foil (as shown in fig 2) at different locations. The pressure obtained at various places are recorded and the results are in close comparison with the conventional pitot tubes.

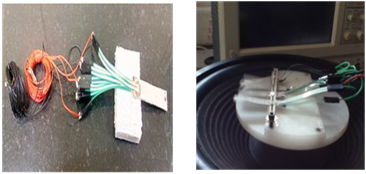

PVDF as a dynamic pressure sensor where different thickness of PVDF film is fixed inside in an acrylic device (as shown in fig 3) with a pressure inlet. The response of PVDF is taken at both atmospheric and absolute pressure condition. The results are under progress.

Pressure Sensor

Energy harvesting using PVDF sensor Energy harvesters are designed, developed and fabricated with different configuration like unimorph, bimorph, multimorph and array (shown in fig 4). The devices are subjected to mechanical vibrations and the output voltage is maximised by fine tuning the resonance frequency of the individual device. The output achieved from a multimorph harvester device is 11 V peak to peak.

Energy Harvesting Devices in multimorph and array configuration respectively

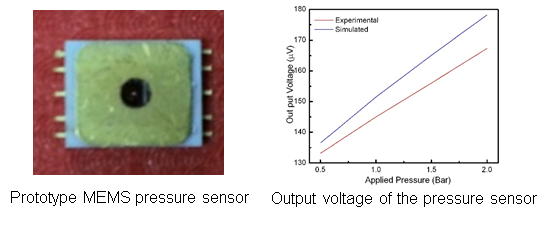

3. PZT Thin Films for MEMS

Materials Science Division of CSIR-NAL has been engaged for more than half a decade on the development of PZT thin films and coatings on various metallic, composite, polymer, Silicon substrates and real structures. The driving force of the research was its high demand in the field of smart sensors and actuators. The usual advantages and merits of any coating like large area coverage, devoid of any bonding layer, ease to cover complex geometries remains the same in the case of PZT coating with added advantage of having improved tensile and flexural strength over bulk piezoceramics and piezopolymers based on the choice of substrate material.

High quality PZT (near morphotropic phase boundary composition) thin films of thickness from 300 nm to 1 µm have been prepared on silicon wafer and characterised for physical, electrical, mechanical, ferroelectric and piezoelectric properties. These properties are reproducible and at par with the commercial product (compared with international supplier, Inostek, Korea). The production route (in clean room atmosphere) of 2 inch PZT coated wafer is qualified the test for its further use in microfabrication.

The PZT coated silicon wafer was used to develop dynamic pressure sensor. MEMS fabrication techniques were employed for this development. The developed pressure sensor showed satisfactory performance with a resolution of 100 mBar. The efforts are on for realising the product of this sensor.

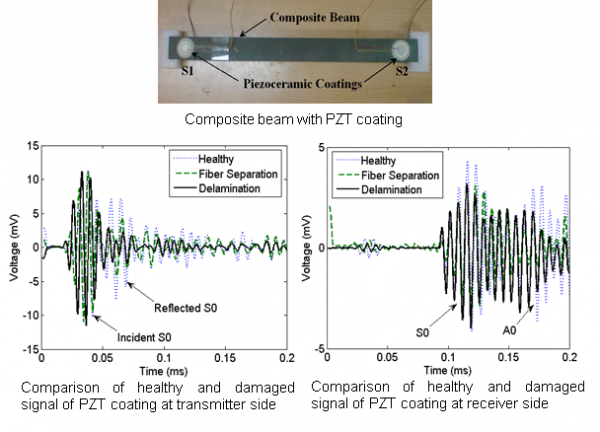

Insitu piezoceramic coating for Structural Health Monitoring (SHM) and Flapping wing

Insitu PZT based piezoceramic coating has been developed on regular and irregular surfaces of aerospace grade Aluminium metals and composites (CFRP and GFRP) with dual functionality as transmitter and receiver of ultrasonic waves.The coating has been successfully tested for local & global structural health monitoring and found to be very promising for damage detection of composite structures (delamination, fibre separation, fibre cut) and metal components. Various types of damages have been detected with their severity by employing this coating. The coating has proved its usefulness in field applications by qualifying stringent tests.

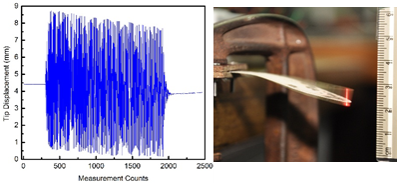

Similar Piezoceramic coating with different material composition was used for mimicking the flapping motion of dragonfly wing. Initially, the wing model was simulated and design parameters were optimized. The simulated result of dragonfly wing with optimized parameter showed 8 mm displacement at resonance which was validated experimentally.

Experimental result of wing tip displacement and a closer view of the flapping wing

4. Thermoelectric Materials and Devices

Materials Science Division is actively involved in the research and development of Thermoelectric (TE) materials and devices for past two decades. Many materials suitable for TE cooler and power generators have been developed. Table 1 gives the summary of all the materials developed and characterized with their figure of merit (ZT).

Table 1: List of TE materials developed

|

Below room temp. |

Temperature Range |

||

|

400K |

650K |

800K |

|

|

Bi-Sb : ZT~2 at 80K (Reported) ZT =0.4 at RT (Achieved)

|

P & n type Bi-Tealloys : ZT ~ 1 (Reported) 1.2-1.4 (Achieved)

Prototype Cooler and generator fabricated |

Zn-Sb alloys: ZT for p type 0.7 (Reported at 300oC) and 0.68 (Achieved) Doped and undopedCoSb:~ 0.4 (Reported and Achieved) Prototype generator Fabricated |

AgPbSbTe (LAST): Best TE material reported so far; ZT = 2.1 Achieved ZT 2.4 through nanostructuring Pure and doped PbTe: ZT~1 (Reported and Achieved) |

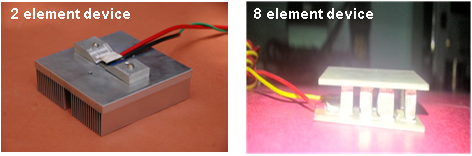

Several prototype TE generators and coolers were fabricated using in house developed materials. p and n legs from BiTe, CoSb, PbTe and BiSb based materials were tested for their device performance. Prototype TE cooler (two element) and TE Generator (eight element device) fabricated out of BiTe and CoSb materials. A 25o temperature difference was achieved for BiTe based TE cooler. Maximum power output achieved was 4W/m2 for 8 element TE generator for a temperature gradient of 400oC. The group has acquired the knowledgebase for the development of thermoelectric devices and to synergize the same with solar thermal conversion.

Prototype TE cooler Prot otype TE power generator

The work on oxide based thermoelectric materials were initiated for the need of high temperature (up to 1100 K) industrial, aircraft and automobile waste heat recovery as the oxide materials have advantage in terms of its chemical and thermal stability, easy processing and cost point of view. The work has been directed towards development of high-density n-perovskite and p-layered cobaltate based materials through hot-press sintering, characterization of thermo-physical properties (Seebeck coefficient by quasi-steady-state 2-probe arrangement and electrical resistivity through 4-probe Delta mode) to fabrication and testing of prototype module for power generation in the range of milliwatt. Presently, work is underway towards possible application for energy harvesting from engine exhaust waste heat to power the sensors and wireless sensor network. Further indium oxide based thermoelectric materials are being explored as high temperature sensor for gas turbine engine.

5. Mutiferroic materials for non-conventional photovoltaics

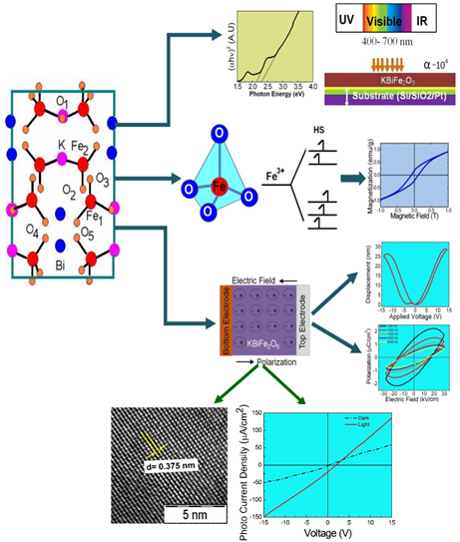

Harvesting solar energy using multiferroic material is a promising and emergent field of research. Modified Bismuth ferrite (BFO) based multiferroelectric materials have been studied for non-conventional photovoltaics. Photons of wavelength λ > 464 nm, accounted for more than 80% of solar spectrum, is not absorbed by BFO due to its higher band gap. Lowering the band gap of such material without affecting its ferroic (ferroelectric and magnetic) properties is the challenge but necessary to obtain higher photovoltaic conversion efficiency. It was possible to reduce the band gap of BFO to 1.6 eV from 2.7 eV by consistent research. After bandgap modification optical sensitivity of the material improved substantially in the wavelength range λ > 464 nm and showed promising photovoltaic properties. This special class of material with coupled ferroelectricity, ferromagnetism, optical and photovoltaic properties seems to be attractive for multifunctional applications.

Schematic representation of mutiferroic properties of low band gap KBFO thin film

6. Radar Absorbing Materials for Stealth Applications

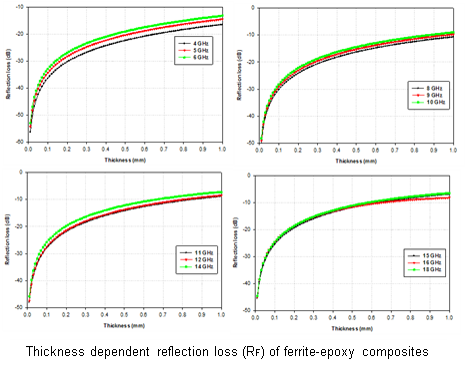

Radar absorbing materials (RAM) are important component for strategic airborne system that reduces the radar cross section (RCS) for stealth vehicle. Ferrites (spinel and hexagonal) are considered to be suitable candidate to develop composite RAM due to their optimized permittivity and permeability within X-band region. Since last two years, Materials Science Division is involved in developing Ferrite-epoxy composite as contour structure through resin-cast technique and near-flexible film by tape casting technique. The work is underway to fabricate larger dimension film and testing for RCS reduction in collaboration with Centre for Electromagnetics.

English

English हिन्दी

हिन्दी