ENERGY

Coatings for solar thermal power generation

In an effort to meet the ever increasing energy demand of the country, the Division has developed spectrally selective transition metal nitride/oxide/carbide based coatings for high-temperature photothermal applications by sputtering process (US07585568, IN257392, PCT/IN2012/000451, PCT/IN2013/000549, 2226DEL2014). The promising coating exhibits an exceptional thermal stability in air up to 580°C under cyclic heating conditions for 200 h on SS304 substrates. The technology know-how for the commercial production of these absorber coatings is available with the Division. The Division has also developed solar selective paint coating containing oxide based pigments. Recently, carbon nanotubes and reduced graphene oxide based coatings have also been developed for solar thermal applications.

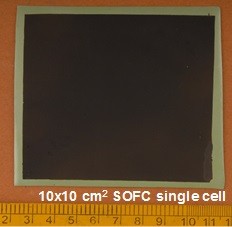

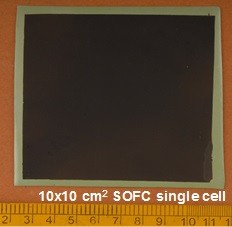

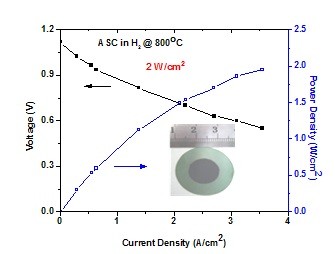

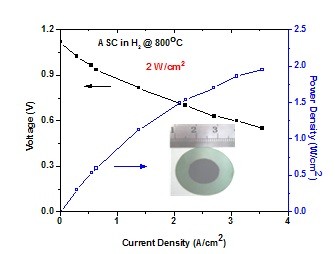

Solid oxide fuel cells (SOFC)

The Division has a strong R&D base in the area of fuel cell technology. Coatings and functional layers for high/intermediate temperature SOFCs have been fabricated by plasma spray, solution precursor plasma spray and tape casting processes by using in-house synthesized and commercially available materials. State-of-the-art electrolyte/anode supported SOFC single cells have also been fabricated and tested. Hydrocarbon compatible SOFC single cell has been developed with a power density (Wmax) of ~880 mW/cm2 using methane as fuel at 800°C (2338DEL2015). Anode supported SOFC button cells developed with gadolinia doped ceria as interlayer have exhibited Wmax of ~2 W/cm2 at 800°C. Recent efforts are focused towards SOFC stack design fabrication and testing. Simulation on SOFC design and optimization has also been initiated.

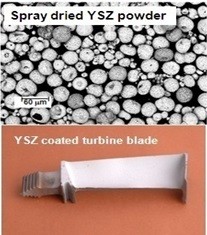

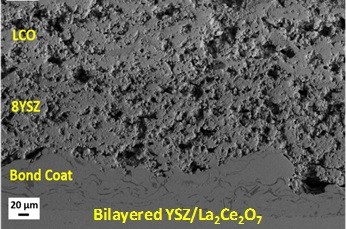

Thermal barrier coatings (TBC)

A new class of plasma spray grade TBC topcoat powders has been indigenously prepared. The performance of SED developed YSZ TBCs is at par with benchmark coatings available elsewhere. For an industry sponsored project, blocky angular shaped YSZ particles were successfully transformed to plasma sprayable grade spherical particles. The coating was evaluated and found to be promising for TBC application. Furthermore, electrodeposition process has been explored to develop the bondcoats. Currently, development of bi-layered TBCs is in progress to simultaneously achieve better thermal compatibility, lower thermal conductivity and spallation resistance. Activities on simple and cost effective suspension plasma sprayed multilayered TBCs (YSZ/Gd2Zr2O7) have been initiated to achieve columnar microstructure.

Erosion Resistant Coatings

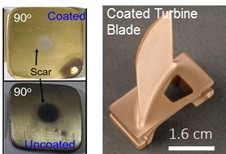

Erosion of gas turbines by air borne particles such as dust, sand and fly ashes ingestion affects the gas path components. The damage of the components such as stator vanes or rotor blades can lead to the structural and aerodynamic engine-performance deterioration and in extreme cases leads to catastrophic failures during service. As a result, maintenance cost, unscheduled removals, and fuel consumption/emissions increase. Apart from this, mission completion rates, safety and readiness decreases. Erosion resistant nano-layered multilayer coatings of Ti/TiN have been developed on compressor blades of turbine engines. In these coatings presence of a large number of sharp interfaces and difference in shear moduli between the two phases improved the erosion resistant performance by a factor of ~70 compared to uncoated Ti6AlV substrate at 400⁰C as per ASTM G76-13 standards.

Erosion of gas turbines by air borne particles such as dust, sand and fly ashes ingestion affects the gas path components. The damage of the components such as stator vanes or rotor blades can lead to the structural and aerodynamic engine-performance deterioration and in extreme cases leads to catastrophic failures during service. As a result, maintenance cost, unscheduled removals, and fuel consumption/emissions increase. Apart from this, mission completion rates, safety and readiness decreases. Erosion resistant nano-layered multilayer coatings of Ti/TiN have been developed on compressor blades of turbine engines. In these coatings presence of a large number of sharp interfaces and difference in shear moduli between the two phases improved the erosion resistant performance by a factor of ~70 compared to uncoated Ti6AlV substrate at 400⁰C as per ASTM G76-13 standards.

Anti-reflection coatings

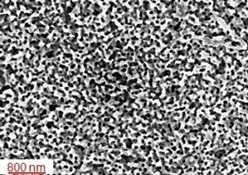

A simple vapor phase etching method has been used to fabricate broadband quasi-omnidirectional AR nanoporous surface on glass which exhibits an average visible transmittance of 96.5% (c.f., 90.5% for plain glass). These surfaces are being developed for applications in PV, solar thermal, display devices, optical devices, etc. (1843DEL2015). Spin off of this work is in the fabrication of transparent heat mirrors for energy efficient windows and hybrid solar cells.

English

English हिन्दी

हिन्दी