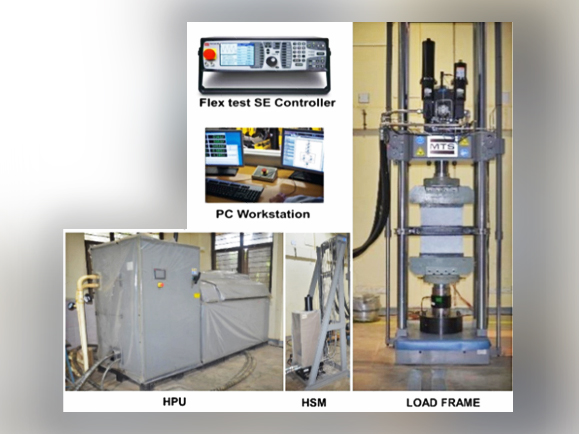

The fatigue-rated test facility consists of a axial loading 4-column load frame. The vertical testing space measures 2100 mm, while the depth space is 400 mm, complete with a movable upper crosshead.

The actuator has a dynamic load capacity of ±1000 kN and a stroke of ±75 mm. The load cell is mounted on a fixed base of the machine. A servo valve drives the actuator, allowing for a stroke of ±10 mm at a frequency of 1 Hz. The Hydraulic Power Unit (HPU) operates at a pressure of 210 bar with a flow rate of 200 L/min.

The facility is equipped with fatigue-rated hydraulic grips and wedges designed to hold flat plates with dimensions of 200 mm by 200 mm and thicknesses ranging from 10 mm to 35 mm, featuring adjustable clamping pressure. The tests can be conducted in either force control or load control mode.

CSIR-NAL has been actively engaged in the development and certification of civil aircraft programs. This system is used for the design and development of composite airframe structures. The specifications are created with consideration of the size of the test panels that need to be tested to obtain the necessary data for damage tolerance studies.

Damage tolerance studies on composite structures; Studies on structural health monitoring for anticipated defects in composite materials. Fatigue testing of panels to study impact damage growth. Panels post-buckling studies etc.